JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY WU800 6 Axes Interpolate Y-Axis Dual Electric Spindle Dual Upper Power Turret Machine101

1. The extraction process of JSWAY covers a few techniques. The product is processed with the mature digging technology and high-tech purification workmanship.

2. This product is in accordance with the quality standards of the industry.

3. This product is provided in different grades and qualities so that it can serve all purposes and requirements.

4. The product has covered most of the provinces and cities in the country and has been sold to many overseas markets.

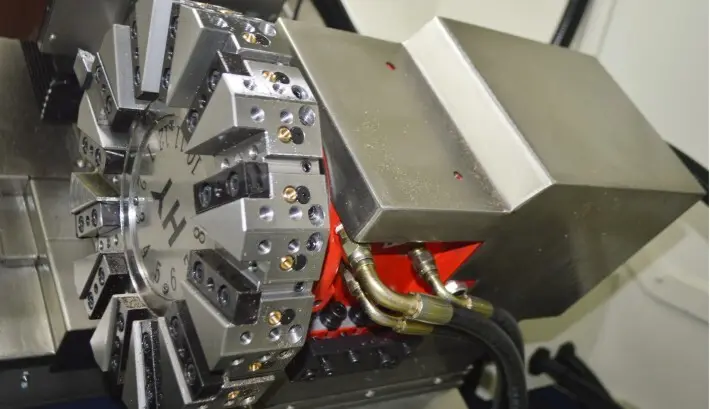

B8D automatic turning, drilling, milling and tapping combination cnc machine

Feature of B8D

1.Y-axis has engraving function.

2. This machine is for turning, side milling & drilling.

3.Y-axis has 4 lateral & endface living tools(or 5+5 optional)

4. Japan gear, low souds, high precision.

5.Max.living tool speed up to 4500rpm.

Technical parameter of cnc lathe machine tool B8D/ B10D

| Item | B6D | B8D |

controller | Optional system | Syntec/Fanuc | Syntec/Fanuc |

Spindle | Spindle bearing | NSK17016/ NSK17014 serie | NSK17016/ NSK17014 serie |

Spindle taper | Morse 6# | Morse 6# | |

Spindle nose type | A2-5 | A2-5 | |

Capacity | Spindle bore | ¢56 mm | ¢56 mm |

Max. material diameter | ¢45 mm | ¢45 mm | |

Max. machining diameter | ¢350 mm | ¢350 mm | |

Max. length of machining | 230 mm | 230 mm | |

Max. travel of x-axis | 725 mm | 725 mm | |

Max. travel of Y-axis | 340 mm | 340 mm | |

Max. travel of z-axis | 230 mm | 230 mm | |

X/Y/Z -axis fast moving | 36 /36/20mm | 36 /36/20mm | |

Positional accuracy | 7 um | 7 um | |

Reposition accuracy | 7 um | 7 um | |

Machining accuracy | 10 um | 10 um | |

Repeat machining accuracy | 10 um | 10 um | |

Motor | Spindle servo motor | JAPAN YASKAWA 4.4KW/SHENZHEN INOVANCE 5.5KW | JAPAN YASKAWA 4.4KW/SHENZHEN INOVANCE 5.5KW |

Spindle speed | 3000r/min (5000r/min) | ||

X-axis servo motor | JAPAN YASKAWA 1800W | JAPAN YASKAWA 1800W | |

Y-axis servo motor | JAPAN YASKAWA 1800W | JAPAN YASKAWA 1800W | |

Z-axis servo motor | JAPAN YASKAWA 850W | JAPAN YASKAWA 850W | |

Living tool servo motor | JAPAN YASKAWA 750W | JAPAN YASKAWA 750W | |

Tool | Turret tools | 8 | 8 |

Living tools | 3 lateral & endface living tools | 4 lateral & endface living tools | |

Others | Power unit tool holder | ER25 | ER25 |

Lubricant volume | 2L | 2L | |

Lubricant oil type | 32# | 32# | |

Hydraulic power unit volume | 70L | 70L | |

Hydraulic oil type | 46# | 46# | |

Table to spindle center height | 63mm | 63mm | |

Lathe bed | 30° slant bed | 30° slant bed | |

Total installed capacity | 4.4KW | 4.4KW | |

N.W | 3700KG | 3750KG | |

SIZE | 2400×2050×2090mm | 2400×2050×2090mm |

Detailed Images

Plumbing,Hardware,Furniture,Medical Instruments,Watch,Ornaments,E-cigarette and so on.

Our Service

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front

in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,

2-3 tools on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,

We can also according to your need to change the configuration. Thus pls provide us your

machining drawing, we are very glad to design a specific process solution for you and

recommend you a proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and

strong machine tool research and development capability. We are very willing to offer you

customized highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more

quickly and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy

all the Equipments for your market ,at the mean time the customers can enjoy the long-term

technical advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term service

to out customers.

Welcome to contact us if need any more information.

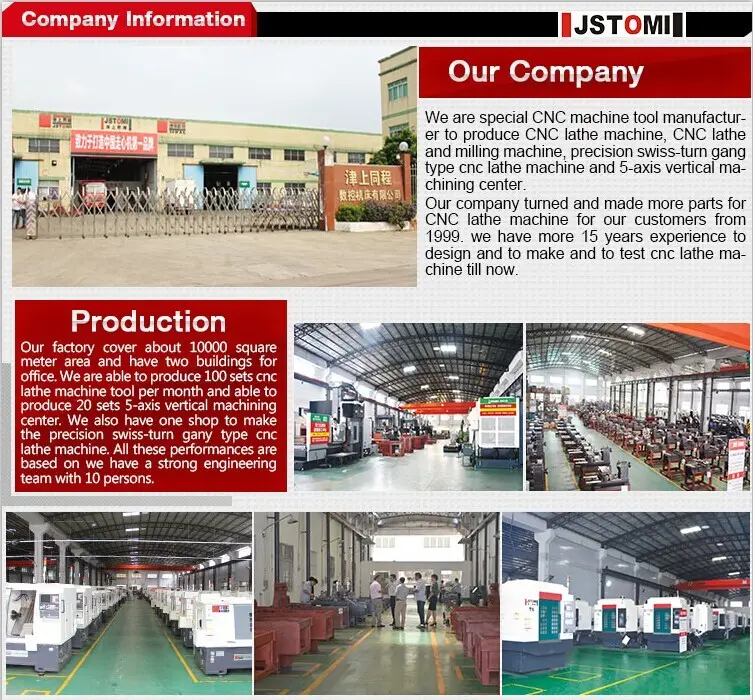

Company Features

1. As time changes, JSWAY has been always doing its utmost to provide trending .

2. At present, we have explored markets in Australia, America, the Middle East, and other countries. These customer networks have helped us grow into a stronger competitor.

3. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. will use cultural advantages to develop high-quality to meet market demand. Ask! JSTOMI CNC Machine insists on taking the market as our business direction. Ask!

We hold "Pursuing the Zenith Technology and Quality" as our management concept all the time. Relying on absorbing world leading crushing and powder processing technology, advanced management and quality control system, as well as our full efforts, ZENITH has earned high reputation among our customers. - ZENITH

mobile aggregate crushing plants introduction

mobile aggregate crushing plants is equipped with primary ,secondary, tertiary crusher as well as screening machine.

mobile aggregate crushing plantss contain Two types:Tire Type Mobile Crushing & Screening plantand Crawler type mobile crushing & screening plant.

Tire Type mobile aggregate crushing plants

This series mobile stone crushing stationis the crushing equipments for rocks and construction waste, which is exploredand developed by our company. It expands the conception of primary andsecondary crushing operation.

Crawler type mobile aggregate crushing plants

Crawler type mobile crushing & screening plant is designed and researched by our experiencedengineers according to the customers' requirement. It is of high costperformance,reliable & beatiful structure. Its technology is as advancedas the internationl level. It is widely used in road & bridge construction,metallurgy and other fileds to crush and screen.

Features of mobile aggregate crushing plants :

1. Incorporated design.

2. Truck mounted .

3. Quick road transportation.

4. With support legs on truck,quick to set-up.

5. Manoeuvrability.

This series of mobile aggregate crushing plants incorporates all the equipments together on one truck, which has high chassis, narrower body compared with other trucks, this ensure the crushing plant be easily transported on highways and moved to crushing sites, so mobile aggregate crushing plants is able to achieve on-site crushing without material transporting from one place to another place. In addition, the lengthened plant is able to transport the final products to the motor-lorry directly. The mobile aggregate crushing plants can start to work soon even in the bumpy ground without re installation, so it saves more time and money than fixed crushing plant which needs to install individual equipment one by one. mobile aggregate crushing plants can work independently or together with other devices according to coarse crushing or fine crushing requirements. Side discharging chute supports more screening and transporting ways. Diesel generators of the incorporated plant cannot only supply power for this mobile aggregate crushing plants, but also supply power for other plants of the process flow.

1. Easy to transport

mobile aggregate crushing plants has on-board chassis, short wheel base and tight turning radius, which is convenient for road transportation, especially for driving to crushing sites that are difficult to access.

2. Greatly reduce material transportation cost

mobile aggregate crushing plants crush the material on site, without transporting the materials for off-site crushing, so the material transportation cost is greatly reduced

3. Wide applications

According to different customers’ requirements,mobile aggregate crushing plants plant can be operated as independent units, or as two-stage crushing plant with primary and secondary crushing, or as three-stage crushing plant with primary, secondary, and tertiary crushing. Likewise, portable plant can be easily adjusted to suit the crushing application by choosing feeding to crusher or feeding to screen options.

4. Reliable performance and convenient maintenance

Normal belt conveyor can be used for conveyance of material, which is of mature technology, simply operation,easy maintenance, and low investment.

5. Customized production and flexible configuration

Based on customers’ site, material, and particle shape requirements, we can provide the customers with special mobile aggregate crushing plants plants, such as self-load belt conveyor, multiple machines combined type, single machine type.

If you are interested with our products, please don't hesitate to contact us. You can tell me the following questions, Then I can send you accurate quotation soon, including additional discount!

1. Which machine do you need? like stone crusher, grinding mill or beneficiation machine, etc.

2. what is your raw material plan to process? like limestone, granite or inron ore, etc.

3. The capacity you need. Like 100 tones per hour or 2000 tones per day.

4. Your contact information. Both Email and phone number are essential, we can contact you easier.

Now, please click the following contact to send us email !

↓↓↓