JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

high quality small cnc lathes for sale gang online for car parts

- Based on customer demand, JSTOMI provides quality services for customers and chases for long-term and friendly cooperation with them.

1. JSWAY conventional lathe machine is designed with high standard. It is designed to meet, tested or compliant with such international standards as IP Protection, UL, and CE.

2. This product provides structural stability. It is able to even out any stress on the building by dispersing kinetic force throughout the entire frame and structure.

3. Our products are admired for their huge development prospects.

Core product advantages

Machine parameter

PARAMETER | ||

|

| B8D |

CAPACITY | Spindle bore | 56 MM |

Max. material diameter: | 45 MM | |

Max swing over bed | 350mm | |

Max. length of machining | 100 mm | |

Max. travel of X-axis | 630 mm | |

Max. travel of Z-axis | 300 mm | |

X/Y/Z fast moving | 36/20/36m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | |

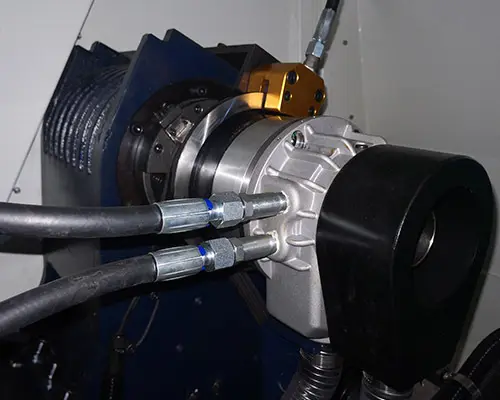

MOTOR | Servo motor | 5.9KW with magnet ring |

Spindle speed | 5000 rpm/min | |

X-axis servo motor | 1.3KW | |

Z-axis servo motor | 1.3KW | |

Y axis servo mot0r | 850W | |

Living tool servo motor | 1.3KW | |

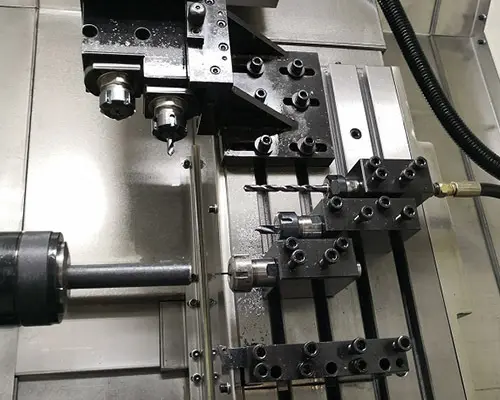

TOOLS | turret | 8/12 tools |

OTHERS

| Total installed capacity | 12 KW |

Size | 2200X1723X2023 | |

N.W. | 2950KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CFG46X | M46X | CFG46X | M46X | |

COLLET | 4-45mm | 4-45mm | 5-100mm | 5-100mm |

CHUCK | 4-160mm | 4-200mm | 5-100mm | 5-100mm |

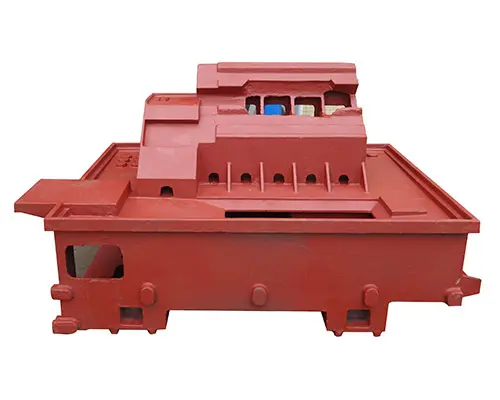

Details of the figure

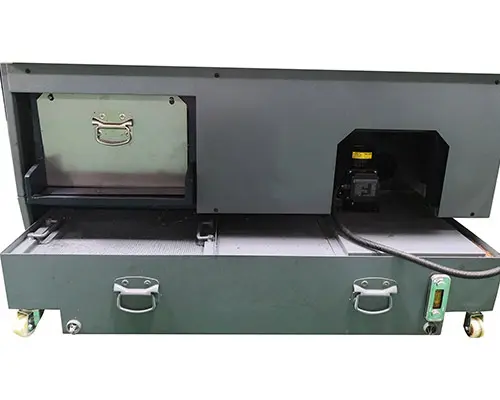

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is well-known in the domestic market. We have been appraised as reliable and credible manufacturer of conventional lathe machine.

2. We possess a dedicated design team. They can constantly improve the design value of our products by being involved in every stage of the design cycle.

3. Our goal is to improve customer service in a significant way. We will endeavor to localize all the product services by establishing our branch companies for the worldwide channel to guarantee 100% customer satisfaction. Our company bears social responsibilities. We are now working to incorporate ESG elements into management/strategies and improve how we disclose ESG information to our stakeholders. We constantly seek to improve energy and resource consumption during production by consistently reviewing our processes and implementing individual site initiatives such as eco-efficient lighting, insulation, and heating systems.