JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

good quality cnc swiss lathe aixs supplier for plant

1. The materials employed in the production of JSWAY cnc swiss lathe is up to the international standard. It can be offered at a favorable price

2. The product enjoys high reputation in the market and has a great market application prospect. The product is versatile, flexible and highly accurate

3. The product is anti-bacterial. The antimicrobial agent is added to improve the cleanliness of the surface, preventing the growth of bacteria. With a full protective cover, it can prevent the water from flowing into it

4. The product is characterized by its excellent plasticity. When the load is applied to it, it will undergo permanent deformation without cracking. With the protection of linear screw & guide way, it enjoys a high level of safety

5. This product is free of any toxic element or substance. Any harmful materials will be excluded out and it is professionally handled to eliminate these toxic elements. The product comes with OEM service to meet customers' needs

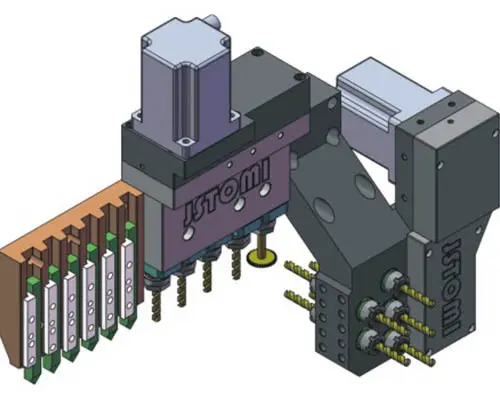

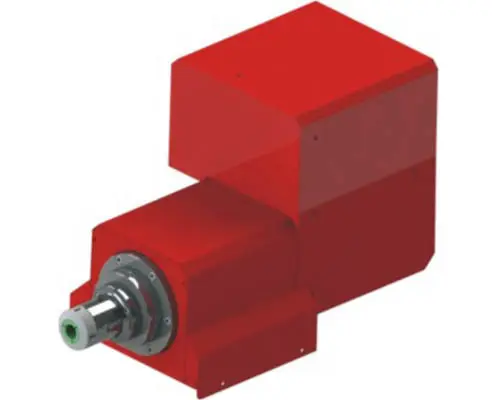

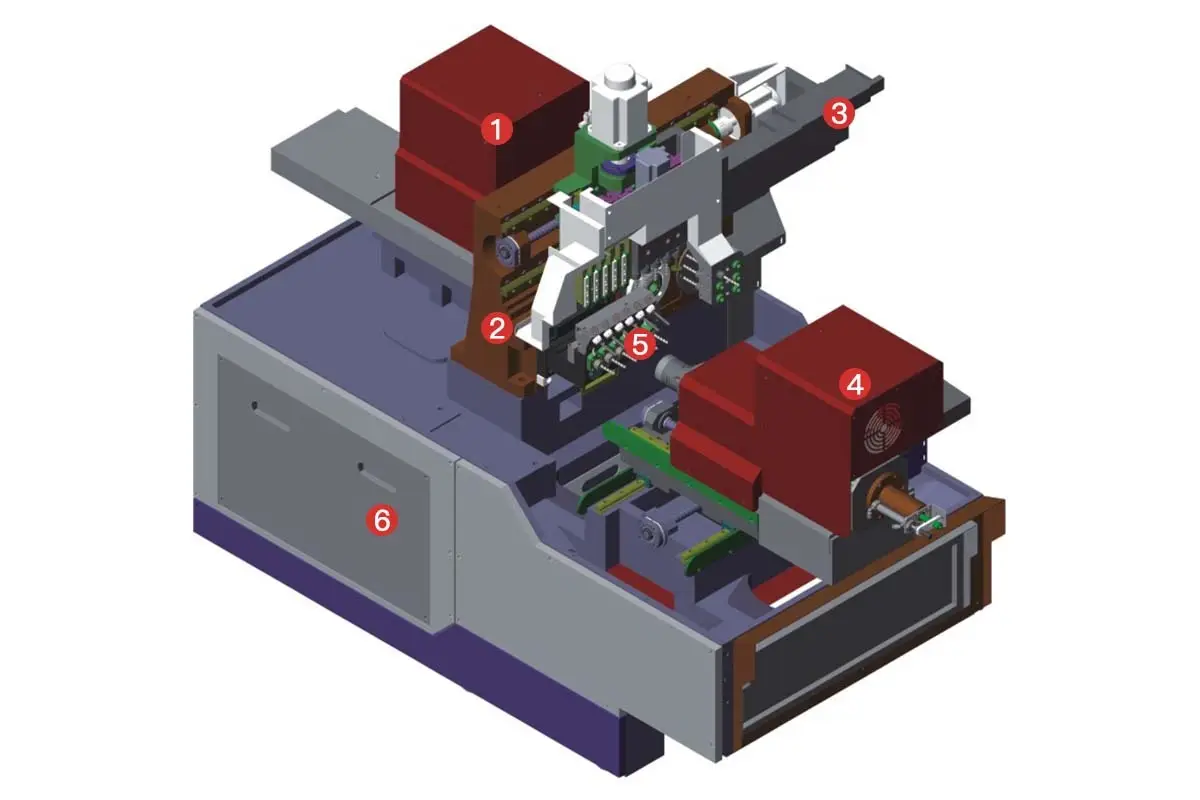

6 aixs big bore double mechanical spindle heavy cutting Swiss type lathe machine A366

Core product advantages

Machine parameter

PARAMETER | |||

A366 | |||

CONTROLLER | System | Syntec | Syntec |

rapid speed | 36m/min(X:24m/min) | 36m/min(X:24m/min) | |

PROCESSING RANGE | spindle clamping diameter | 7-35mm | 7-35mm |

one time feeding material length | 170mm | 170mm | |

spindle max drilling diameter | 14mm | 14mm | |

spindle max tapping diameter | M8*P1.25 | M8*P1.25 | |

Max lateral drilling hole diameter | 10mm | 10mm | |

SPINDLE | S1 spindle power | 4.4KW | 4.4KW |

S1 max speed | 6000rpm | 6000rpm | |

C1 indexing | 0.015° | 0.015° | |

spindle thru hole | 36mm | 36mm | |

SPINDLE TABLE STOKE | fixed sleeve | 170mm | 170mm |

movable sleeve | 170mm | 170mm | |

TOOLS | cutting tools | 6 tools 12*12 or 5 tool 16*16 (optional) | 6 tools 12*12 or 5 tools 16*16(optional) |

S3 lateral power tools | 5 ER16 living tool | 5 ER16 living tool | |

S3 lateral power tools Max speed. | 6000rpm | 6000rpm | |

S3 motor power | 1.0KW | 1.0KW | |

S5 end face tools | / | 5 fixed ER16+3 movavle(optional) | |

S5 max drilling diameter | / | 10mm | |

S5 Max. tapping diameter | / | M8*P1.25 | |

S5 lateral tools Max speed | / | 6000rpm | |

S5 motor power | / | 1.0KW | |

POWER | Y1 Z1 servo motor | 0.8KW | 0.8KW |

X1 servo motor | 1.3KW | 1.3KW | |

DIMENSION | Size( L x W x H ) | 1900*1300*1740mm | 1900*1300*1740mm |

N.W |

| 3450KG | 3500KG |

Company Features

1. With larger manufacture scale, Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has made a stride in international stage.

2. We have a product management team responsible for the life cycle of our products. With their years of expertise, they can improve the lifespan of our products while constantly focusing on the safety and environmental issues at each phase.

3. We stick to the tenet of nurturing corporate civilization consistently. Get info!