JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

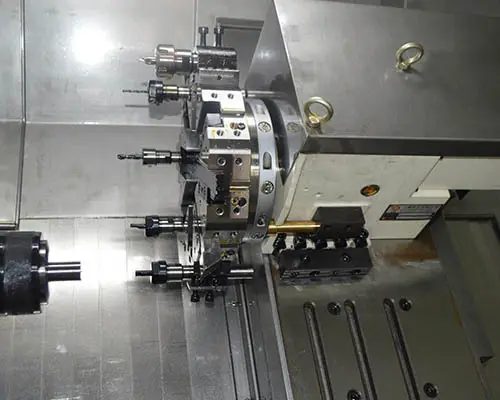

flexible small cnc metal lathe lathes with tailstock for workplace

1. The development of JSWAY cnc lathe mill combo has many design considerations. They are static and dynamic stiffness, operating speed, gearbox, manual and automatic control. The product has been exported to many oversea countries, like UK

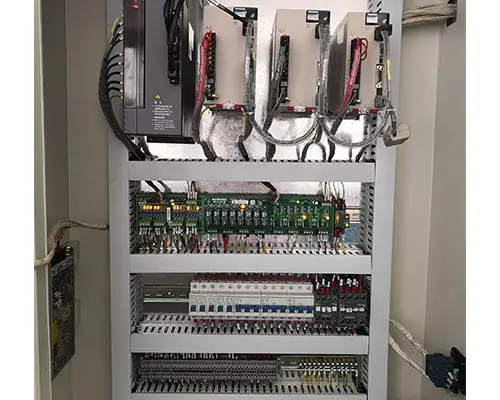

2. The use of the product helps manufacturers cut down labor costs, and shift the investment to other profit-generating things, such as brand advertising. The product is certified under CE and ISO 9001

3. This product is characterized by a stable and reliable operation. It can constantly work maintaining its highest level without any sudden break.

Core product advantages

Machine parameter

PARAMETER | |||

|

| CZG46D | CZG56D |

CAPACITY | Spindle bore | 56MM | 66 MM |

Max. material diameter: | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 720MM | 720 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

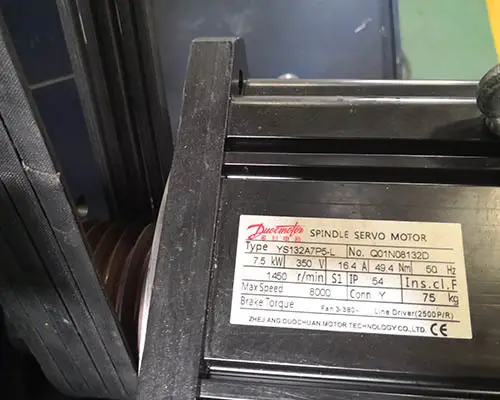

MOTOR | Servo motor | 7.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

TOOLS | Turret | 8+3 | 8+3 |

OTHERS

| Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CZG46D | CZG56D | CZG46D | CZG56D | |

COLLET | 4-45mm | 4-52 | 5-100mm | 5-80mm |

CHUCK | 4-140mm | 4-160mm | 5-100mm | 5-80mm |

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Company Features

1. We have a sales and marketing team scaled for the global market. With their years of experience in the market and wide sales network, they manage to deliver our products to the rest of the world.

2. Our company upholds the "people-oriented" management thought to make our company more perfect. We attach importance to employees' rights to get paid, provide them with the space for advancement, and protect their interest.