JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

CFG46Y2 5-axis y-axis cnc lathe machine

- JSTOMI puts customers first and make effort to provide quality and thoughtful services based on customer demand.

1. The materials of JSWAY are properly labeled, stored and traceable.

2. This product is not affected by disinfectants. The metal materials used have been specially coated, which makes it stand up being cleaned under disinfection environments.

3. The product is durable and anti-aging. It can endure longstanding and monotonous repeated mechanical operation without failure and malfunction.

4. For all things large and small, this product features large compartments to fit people's daily essentials. It can keep all items within easy reach.

Features of 5-axis y-axis cnc lathe machine tool CFG46Y2:

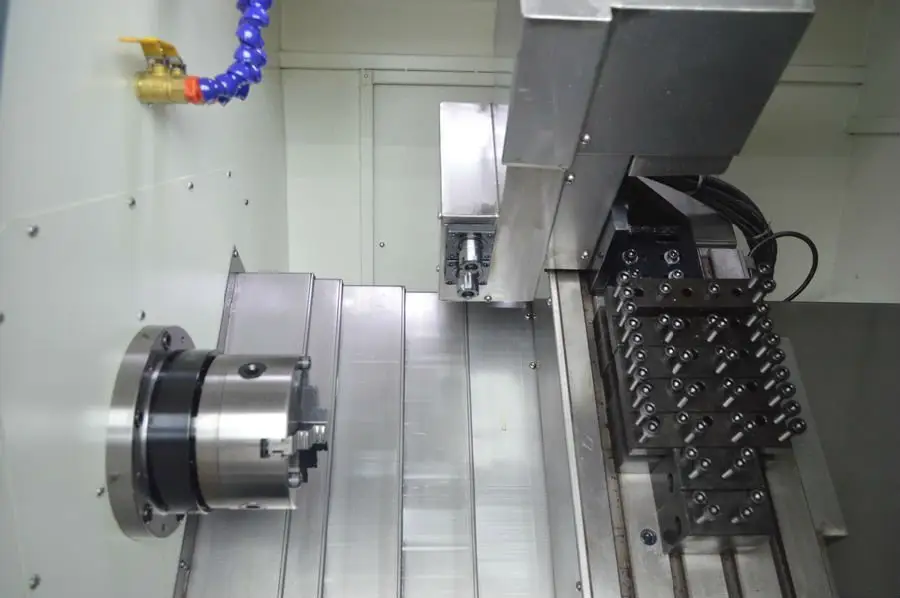

1. Y axis have engraving function.

2. This model is for turning, side milling and drilling.

3. Big space for machining, Z/X axis travel is long.

4. Y axis have 2 living tools; X axis can install 5-7 gang tools.

5. Japan gear, low sounds, high precision for Y axis living tool.

6. Spindle with C-axis indexing function.

Technical parameter for 5-axis y-axis cnc lathe machine tool CFG46Y2

| NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

| Spindle | TaiWan Posa | A2-5/46 spindle |

| X.Z axis servo motor | Japan YASKAWA | 1300 W |

| Y axis servo motor | Japan YASKAWA | 750W |

| Spindle servo motor | Japan YASKAWA | 4.4 KW |

| Spindle servo pack | Japan YASKAWA | 5.5 KW |

| Lead screw/lead rail | TaiWan HIWIN/PMI | C3 , level two |

| Bearing | Japan NSK,Germany FAG | P4 level |

| Coupler for lead Screw | From Germany | high Precision |

| Parameter | ||

| Capacity | Spindle bore | ¢56 mm |

| Max. material diameter | ¢45 mm | |

| Max. machining diameter | ¢350 mm | |

| Max. length of machining | 180 mm | |

| Max. travel of x-axis | 720 mm | |

| Max. travel of z-axis | 280 mm | |

| Max. travel of Y-axis | 100 mm | |

| Rapid speed (x-axis/z-axis) | 36 m/min | |

| Reposition accuracy | 0.005 mm | |

| Motor | Spindle servo motor | 4.4 KW |

| Spindle speed | 3000 rpm | |

| X/Z-axis servo motor | 1300 W | |

| Y-axis servo motor | 750 W | |

| Servo motor for power unit | 750 W | |

| Tools | Gang type tools | 3--5 |

| Total living power tool unit | 2 | |

| Living tool holder size | ER20/25 | |

| Other | Total power | 7KW |

| Size( L x W x H ) | 2070*1580*1870 | |

| N.W. | 2550 KGS |

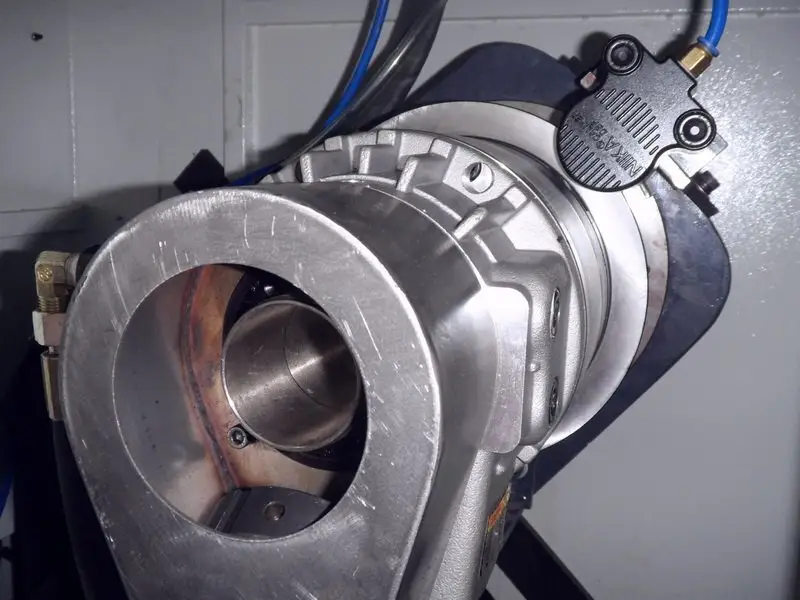

(1)the A2-4 spindle is from Taiwan

(2) use the P4 level NSK bearing from Japan

(3) the high speed up to 6000 rpm.

(4) the max. through bar material diameter is 35mm.

(5) can instal 5 inches maual chuck

(6) can instal 5 inches hydraumatic 3-jaw lathe chuck

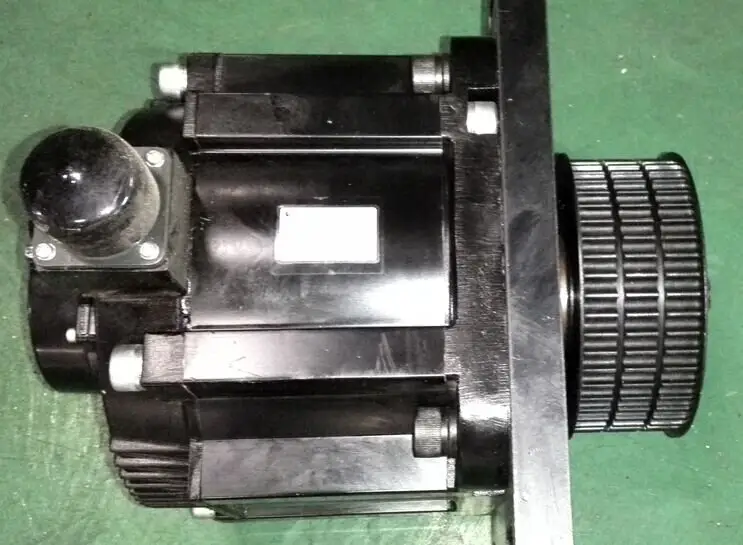

(1)the spindle motor is from Yaskawa

(2) 4.4KW spindle motor

(3) the high speed up to 4500 rpm.

(4) the servo motor can get the bigger torque when low turning

X/Z axis servo motor and servo pack

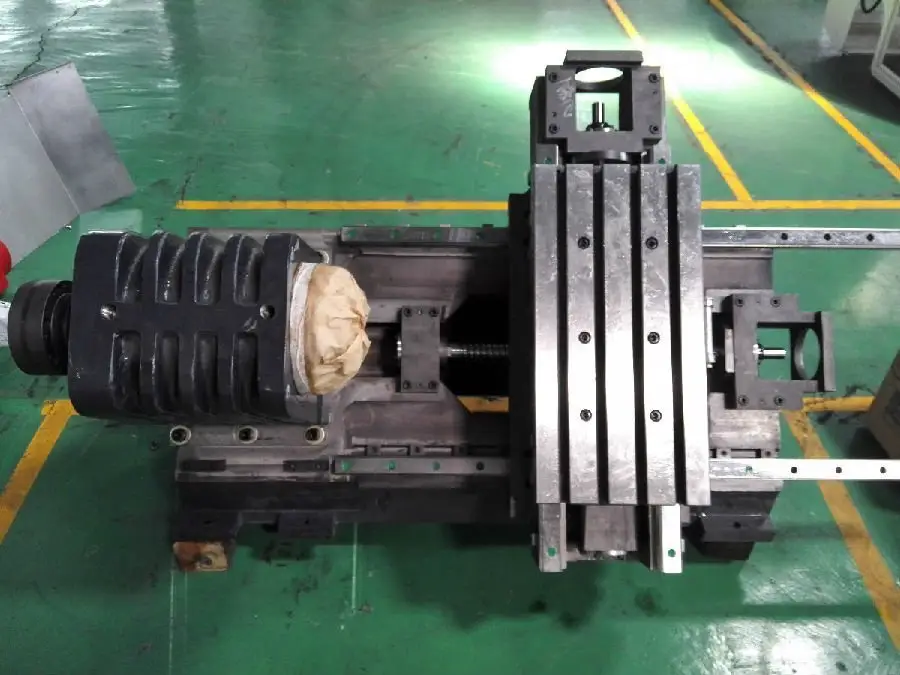

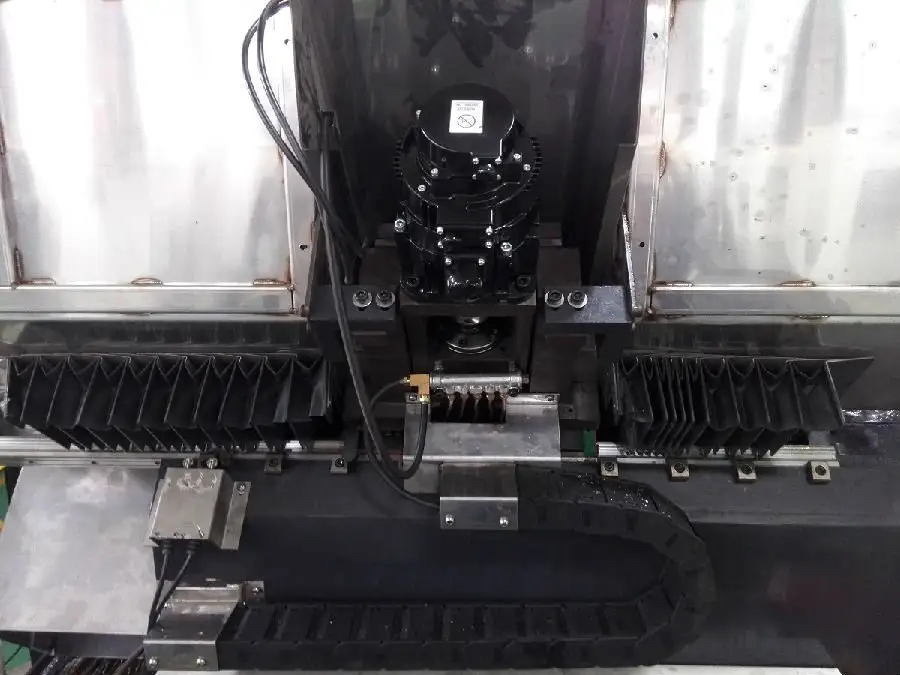

(1) gang type cnc lathe machine body.

(2)X-axis and Z-axis assembly

Linear Guide and BallScrew

NSK bearing

P4 level

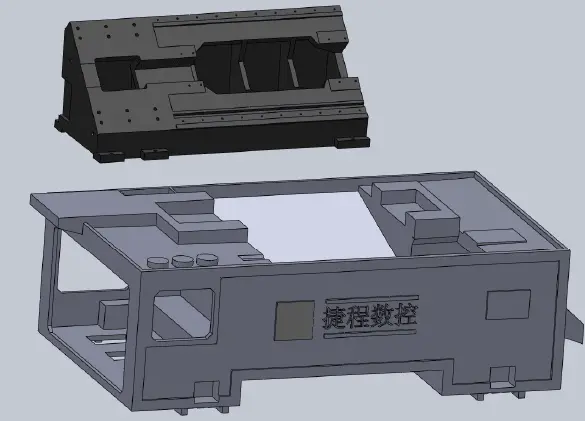

(1) gang type cnc lathe machine body.

(2) X-axis and Z-axis assembly.

(3) slanting bed for gang type.

(4) HIWIN lead screw and couple

(5) NSK bearing.

(1) full cover for gang type cnc lathe machine CFG46Y2 model.

(2) stainless steel for cover.

(3) gang type can instal 6 to 7 tools.

(4) free provide 2 long and 2 short tool holders

(5) Y axis living tool size is ER25, tools diameter is 1~16mm

(1) 13000W YASKAWA servo motor for X-axis

(2) 1300W YASKAWA servo motor for Z-axis

(3)850W YASKAWA servo motor for Y-axis

(4) 1300W YASKAWA servo motor for living tool

(5) 36 m/min for travel speed

1) hydraulic cylinders from TAIWAN.

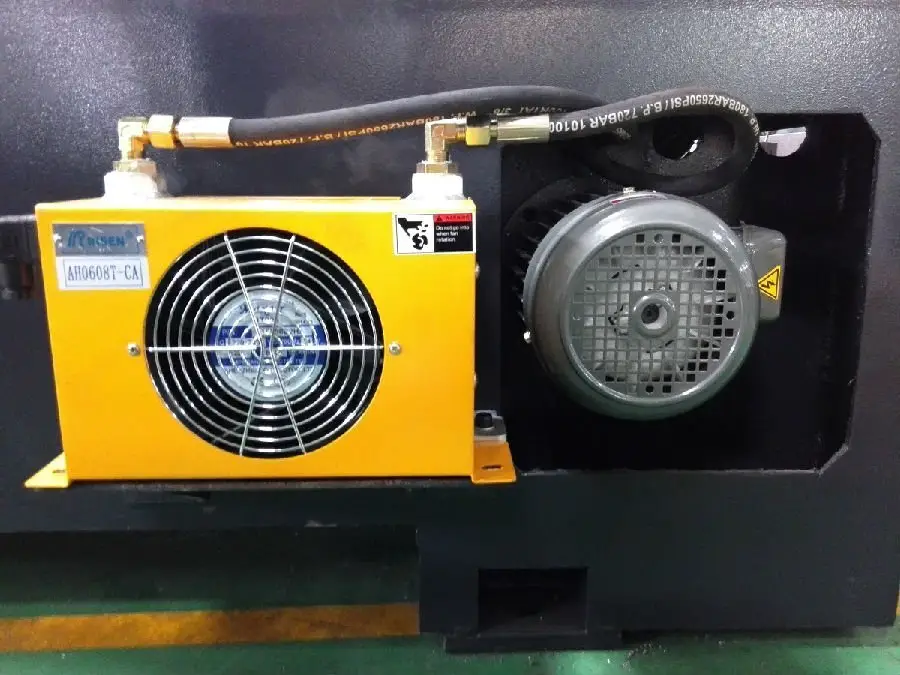

(1) hydraulic cooler

(2) hydraulic pump motor use 2 hp

(1) electrical cabinets for4 axis type cnc lathe machine

(2)YASKAWA servo pack for spindle motor

(3) servo motor driver from YASKAWA for X-axis and Y-axis motor

(4) Schneider switch

(1) controller panel

(2) controller can be change for SYNTEC,GSK and so on

(3) controller can be set in English

(4) we have JSTOMI and JSWAY two logos.

pressure gate

(1) all cnc lathe machine tool with HTS CE certificate

(2) all cnc lathe machine tool with ECM CE certificate

PACKING AS BELOW

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. was established decades ago and has become the global ODM/OEM manufacturer.

2. We are proud to say that is made to be eco-friendly and natural.

3. With fantastic vision, Zhongshan JSTOMI CNC Machine Tool Co., Ltd. intends to become the most aggressive supplier. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. will continue to provide a high quality and professional services. Call! We always provide better service for every customer with . Call!

1.Application:

Our company produces the chipper disc chipper, wood chipper, miscellaneous wood chipper, wood chipper is the production of high quality wood a special wood chipper, widely used in papermaking, particle board factory, and high density fiberboard factory, stubble factory, biomass power plant, wood factory, and other industrial and manufacturer of production preparation section before the preferred equipment. The main cutting raw material is peeling after the trail wood, bamboo, slab materials and cutting time fuelwood excess material, etc.

2.The principle of work:

Timber by feed port into, when wood according to contact to peel and cut blade, along with the cutting knife plate of high-speed rotation to peel and cut, cut cut pieces of wood in the peel and cut indoor by cutting knife plate wind leaf produced by the high speed flow send out.

3.Structure composition:

Mainly by the stand, feed port, cutter, casing, chipping blade and electronic component, the machine can according to need to adjust the peel and cut blade, the production of different specifications and thickness of the chip.

4.Equipment advantage:

1, New chipper large disk chipper, roots chipper, plate cutting machine, wood flaking machine, wood slice machine high output, low energy consumption, wood chip high quality, cost-effective.

2, Chipper disc chipper compact structure, rational layout, easy installation, operation and maintenance convenience, high productive capacity; Cutting log, high quality wood, and wood chip length can be in within the prescribed scope of free adjustment, is the domestic advanced woodworking machinery equipment.

3, Disc chipper production, user can choose according to need model.

1.Q:Are you a factory or trading company?

A:We are a 20 years factory with more than 60 engineers.and have gained the supplier assessment.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Zhengzhou City, Henan Province, China,.You can fly to Xinzheng airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How can I get some samples?

A: We are honored to offer you samples according your inquiry.

4.Q:How does your factory do regarding quality control?

A:"Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end.

Our factory has gained BV,SGS, CCC,ISO certification.