JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

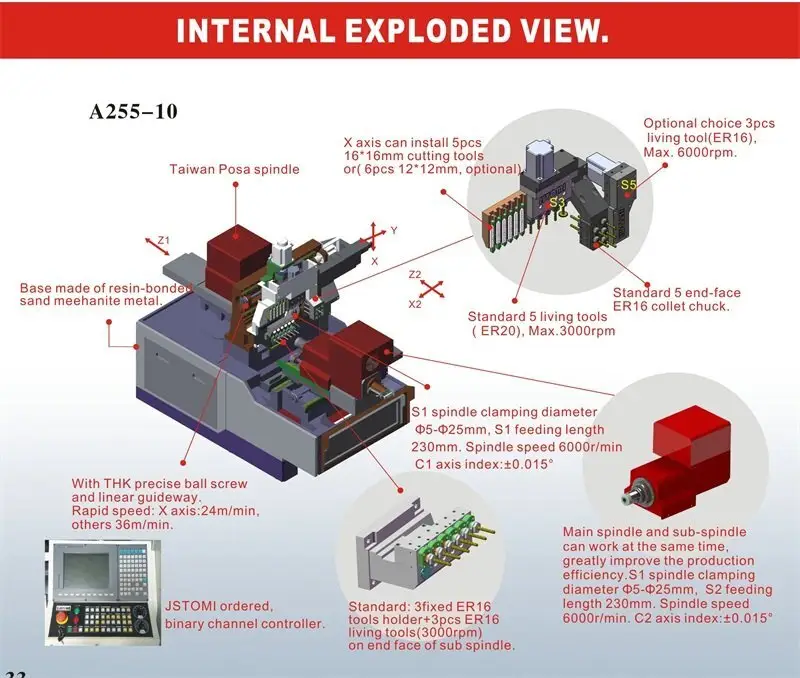

A255-10 Double Spindle Rotary Auto swiss type CNC Lathe Machine

- JSTOMI provides professional, diversified and international services for customers.

1. JSWAY is manufactured by our experts utilizing optimum quality raw materials with the help of advanced technology.

2. The product has remarkable hardness. It is made of metal materials which have excellent mechanical properties such as high hardness and strength.

3. By conducting strict quality management system, the quality of can be assured before its package.

4. JSWAY set up an integrated series of quality assurance system to ensure the quality.

Double Spindle Rotary Auto swiss type CNC Lathe Machine Price

Features:

2. Reduce the frequency of clamping - Enhance Machining Precision

3. Reduce floor area coverage - lower production cost

| Item | A255-10 | |

| Controller | Optional system | Syntec/Fanuc |

Processing Range | Rapid speed | 36m/min(X:24m/min) |

| S1 spindle clamping diameter | φ7-φ25mm | |

| S2 spindle clamping diameter | φ5-φ25mm | |

| S1 spindle max drilling diameter | φ20mm | |

| S1 spindle max tapping diameter | M12 | |

| Max lateral drilling hole diameter | φ10mm | |

| Spindle | S1 S2 spindle power | 4.4KW |

| S1 S2 max speed | 6000rpm | |

| C1 C2 indexing | 0.015° | |

Spindle Table Stroke | Without sleeve & withe sleeve | S1: 280mm( without sleeve) 230mm (with sleeve) S2: 280mm( without sleeve) 230mm (with sleeve) |

| Tools | Cutting tools (optional) | 6 tools 12*12 or 5 tools 16*16 |

| S3 lateral power tools | 5 power tools ER16 | |

| S3 lateral power tools speed | 3000r/min | |

| S3 motor power | 1.0 KW | |

| S4 lateral power tools | 3 fixed ER16 + 3 power tools ER16 | |

| S4 lateral power tools Max speed. | 6000rpm | |

| S4 motor power | 1.0KW | |

| S5 lateral power tools | 5 fixed ER16 + 3 power tools ER16 | |

| S5 max drilling diameter | 10mm | |

| S5 Max. tapping diameter | M8*P1.25 | |

| S5 lateral tools Max speed | 3000r/min | |

| S5 motor power | 750W | |

| Power | Y1 Z1 servo motor | 850W |

| Z2. X2 servo motor | 850W | |

| X1 servo motor | 1300W | |

| Dimension | Size( L x W x H ) | 2300*1300*1800mm |

| N.W | 3800KG |

1. We are a manufacturer of slant bed cnc lathe machine for 10 years ,Technology in the industry is come

out in front.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Our Advantages and quick delivery, Competitive price ,high quality and long term service to out

customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. What accuracy can processed work piece reach?

Machining accuracy is very complicated for it can be affected by people, machine, methods, material

and environment, and machine itself is just one of them; besides, accuracy could mean flatness,

verticality, roundness, alignment or position degrees and so on, it’s hard to make it clear in general

concept. Thus pls provide us your machining drawing, we are very glad to design a specific process

solution for you and recommend you a proper cnc machine model.

2. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools on

table.

3. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can also

according to your need to change the configuration. Thus pls provide us your machining drawing,

we are very glad to design a specific process solution for you and recommend you a proper cnc

machine model.

4. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong

machine tool research and development capability. We are very willing to offer you customized

highly-efficient equipment as long as you have certain amount of needs.

5.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly

and efficiently so that can delivered safely to the designated place as guest.

6. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the

Equipments for your market ,at the mean time the customers can enjoy the long-term technical

advisory services in our company.

7. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term

service to out customers.

Welcome to contact us if need any more information.

Company Features

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is the leader in science and technology innovation in China's industry.

2. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is technologically leading as a manufacturer.

3. We believe that our will also be successful in our client market. For years, we've been focusing on serving clients with our finest and thoughtful service. Call now!

Product Description:

Our cable tray roll forming machine (also called cable ladder roll forming machine) is capable of making different sizes of cable trays through replacing punching moulds. The cable trays produced by this roll forming production line are extensively used in factories and other building because of their accurate robustness. With full and special experience, we can customize cable tray forming machines or cable roll forming production lines according to customers’ profile drawing and specifications. Other high quality equipments, including metal roll forming machine are also provided as you require.

Main Components

Manual Uncoiler

Guide& Feed& leveling unit

Roll Forming System

Hydraulic Cutting

Hydraulic Station

PLC Control System

Output table

Technological process

Uncoiler—Feeding—Leveling—Punching&Cutting—Roll forming—Output table

Processing Flow Chart

Uncoiling- infeed guiding- leveling- punching- rollforming- cutting to length- out put product

Technical parameter

| Items | Specifications | |

|---|---|---|

| Material of coil | Material Width | 200-950mm |

| Material Thickness | 0.8-2.0mm | |

| Uncoiler | 6 tons manual | |

| Forming system | Rolling Speed | 2-4m/min |

| Roller Stations | 24 stations | |

| Roller Material | GCr15quench treatment | |

| Shaft DIA | D65mm | |

| Main Motor Power | 22kw | |

| Cutting system | Material Of Cutting | Cr15 with quench treatment |

| Hydraulic cutting Power | 5kw | |

| Electrical control system | Electric Source | 380V, 50HZ,3 phase |

| Control System | PLC (Panasonic) |

Transportation

All goods will be shipped to your country, containers number will be decided with how many machines you choose.

Installation of the machine

The Individual components of the machine are installed according to the layout and prepared for the commissioning.

The installation comprises of

- Installation by Suhang service technicians.

- The following services are included.

-Installation of the machine components

-Adjustment of the machine components

- Connection of all motors to the control cabinet

-Installation of the required safety devices.

Commissioning of the machine

The components of the machine are commissioned one after the otherl. At the end of the commissioning the machine is ready for production and is handed over.

The commissioning comprises:

-Commissiong by Suhang Service technicians

- Training at the machine

- The following services are rendered

- Run up of the machine components

- Testing of all functions of the machine components

- Start of a fully automatic molding process

- Execution of machine acceptance

Our After-Sales Service Commitments

Suhang hereby solemnly promises: We implement the “three guarantees” service policy for any equipments sold by Suhang, provide free of charge installation guidelines, commissioning and maintenance of the equipments, training of the Buyer’s relevant Operators; and provide technical requirements for the installation and operation of the equipments, technical layout diagrams and other related information, provide a lifetime supply of maintenance and spare parts

The detailed measures are as follows:

1.Guidelines for installation and commissioning of equipments:

Based on the actual situation, to assist and guide the Buyer and Buyer’s technical personnel in the overall installation location, the installation of equipments, and provide Buyer with answers to their questions and related issues;

2.Provide training for operation and maintenance personnel:

Based on the Buyer’s request, Suhang will provide free of charge training of the operation and maintenance personnel;

a) The User (Buyer) can send their operation and maintenance personnel to our factory for learning and training;

b) When Suhang is doing the installation and test running of the equipments for the Buyer, the Buyer can send their personnel to participate.

3.If failure occurs in any of the machines during the “three guarantees” period(one year), then, upon the Buyer’s request, Suhang will eliminate the failure;

4. Suhang will inform all its Buyers about any upgrades and significant product improvements. Suhang will provide equipment modifications based on their costs. Suhang will provide Buyers with high-quality after-sales services in a careful and responsible attitude, provide very strong guarantee for the Buyer’s normal production.

We provide quick and satisfactory customer service, and promise to respond within 24 hours after receiving your complaints by phone or email

Commercial Conditions

1. Port of Loading: FOB Shanghai

2. Delivery time: 50 days after technical clearance and down payment

3. Payment: 40% TT in advance, balance before delivery

4. Assembly and comissioning: Two engineers will visit buyer's workshop for install, commission and training, the salary of our engineer cost USD100 per day. The customer should ensure the pre-installation being carried out appropriately.

5. Warranty: 12 months warranty starting from the date of the successful installation and commissioning of the equipments.