JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

JSWAY professional cheap lathes for sale online for factory

Brand Name:

JSWAY

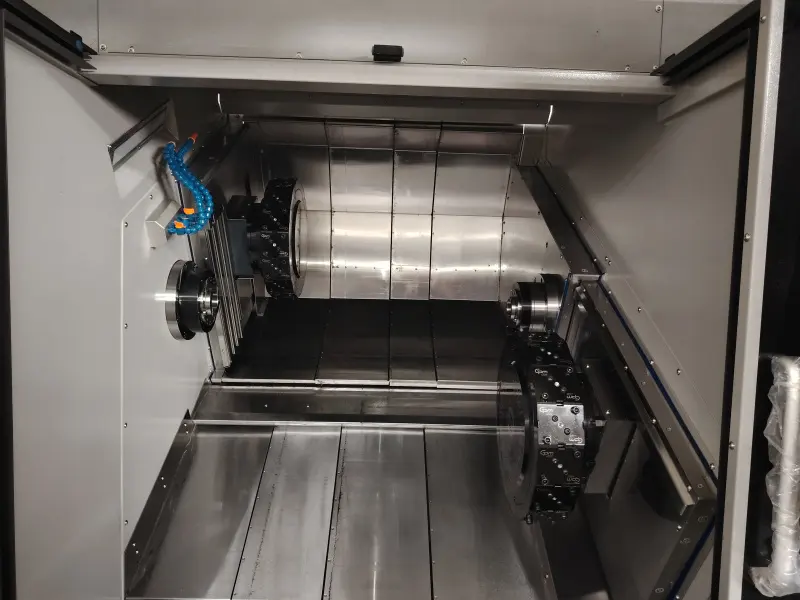

Model Number:

WE800

Supply Ability:

40-60 units per month

MOQ:

1 unit

Payment Terms:

T/T, L/C

Price term

EXW FOB CIF

Payment term

T/T L/C30\% deposite

MOQ

1 set

Nearest port

Nansha, Yantian or Shekou Port in Guangdong Province China

Company Advantages

1. During the production, the quality of JSWAY 3 axis cnc milling machine price is strictly scrutinized in terms of cutting, stamping, welding, polishing, surface treatment, and drying. The product has a high load-bearing capacity

2. This product will help raise the overall production in the economy. Consequently, employment, national income, and the growth rate of the economy will increase. With a full protective cover, it can prevent the water from flowing into it

3. The product produces an exact result every single time. It can repeat the exact same task over and over again with the same level of detail and precision. Swiss lathe machines are capable of simultaneous machining operations. While the workpiece is supported by the guide bushing, multiple tools, including turning, milling, drilling, and tapping tools, can perform operations simultaneously. This significantly reduces cycle times and increases productivity

Company Features

1. JSWAY is a high-tech company which integrates production, R&D, sales and service of cheap lathes for sale together.

2. Guangdong JSWAY CNC Machine Tool Co., Ltd. 's used lathe tooling are integrated domestic and foreign advanced technologies.

3. JSWAY concentrates on supplying high quality service for clients. Please contact us!

1. During the production, the quality of JSWAY 3 axis cnc milling machine price is strictly scrutinized in terms of cutting, stamping, welding, polishing, surface treatment, and drying. The product has a high load-bearing capacity

2. This product will help raise the overall production in the economy. Consequently, employment, national income, and the growth rate of the economy will increase. With a full protective cover, it can prevent the water from flowing into it

3. The product produces an exact result every single time. It can repeat the exact same task over and over again with the same level of detail and precision. Swiss lathe machines are capable of simultaneous machining operations. While the workpiece is supported by the guide bushing, multiple tools, including turning, milling, drilling, and tapping tools, can perform operations simultaneously. This significantly reduces cycle times and increases productivity

Interpolation 6 Axis Cnc Machining Center

Interpolation is used to determine the movement of the cutting tool along a specific path in order to create the desired shape or contour. This process is essential for achieving precision and accuracy in CNC machining operations. There are different types of interpolation, such as linear interpolation, circular interpolation, and helical interpolation, each suited for specific machining requirements.

The multi-axis capability of a 6-axis CNC milling machine enables it to machine complex geometries with ease, including features such as undercuts, compound angles, and contoured surfaces.

Company Features

1. JSWAY is a high-tech company which integrates production, R&D, sales and service of cheap lathes for sale together.

2. Guangdong JSWAY CNC Machine Tool Co., Ltd. 's used lathe tooling are integrated domestic and foreign advanced technologies.

3. JSWAY concentrates on supplying high quality service for clients. Please contact us!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Copyright © 2025 Guangdong JSWAY CNC Machine Tool Co., Ltd. -www.jsway-cnc.com | Sitemap | Privacy policy