JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

4 axis CNC milling lathe machine with Sauter servo turret SY500/S500/SY300/S300 machining center98

1. The raw materials of JSWAY go through demanding qualitative selection criteria in terms of nature constancy and the absence of contaminants.

2. We regard quality as our top priority and ensure reliable product quality.

3. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has complete sample and reasonable prices for .

4. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. will provide delivery and shipping rate to assist customers to make purchase plan.

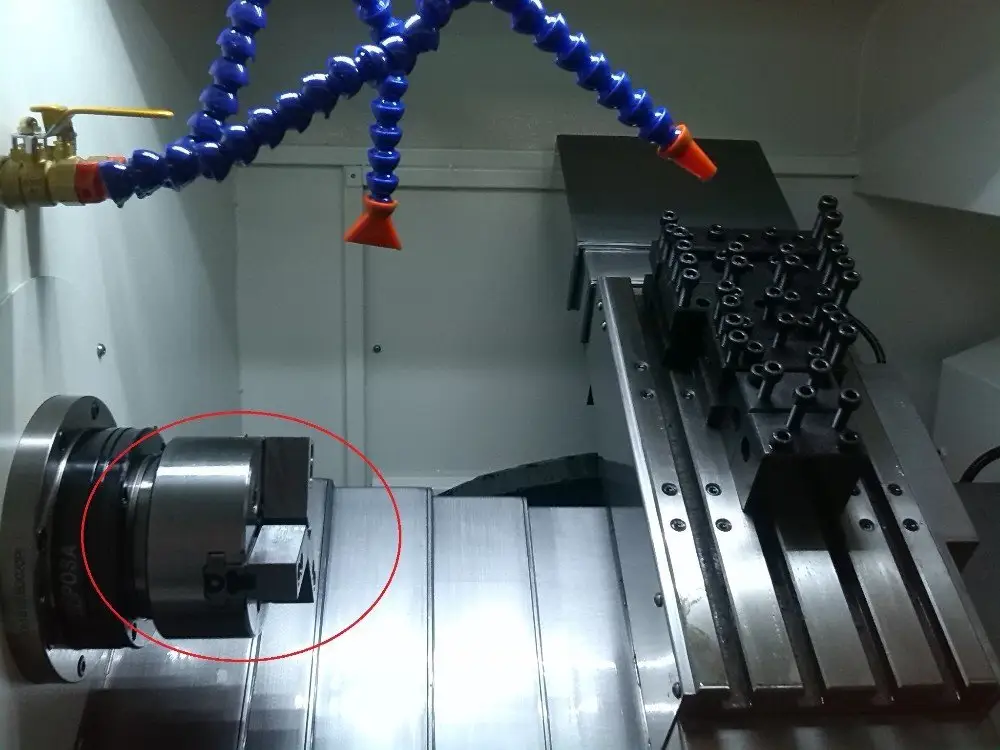

Easy To Install High Speed and Long Service Life 3 Jaw

Power Chuck

Features

1. Patented product, cylindrical form of connection, easy to install, in line with industry

standards.

2. With a large through-hole, high speed and long service life, the chuck equipped with a

standard soft jaw can be used for high-precision machining of clamp and rod parts.

3. It is applicable to all kinds of CNC lathes and automatic feed processing equipment,

(it is available for hollow three-jaw power chuck with rear through-hole structure, and the

connection method is the same as solid pneumatic chuck).

| Model | OP-204 (-) | OP-205 A24 | OP-206 A25 | OP-208 A26 | OP-210 A28 |

| Plunger stroke mm | 10 | 10 | 12 | 16 | 19 |

| Jaw stroke (diameter) mm | 5.4 | 5.4 | 5.5 | 7.4 | 8.8 |

| Max. pull force(kgf) | 14 (1428) | 17 (1730) | 21 (2140) | 33 (3360) | 42 (4280) |

| Max. gripping force (kgf) | 28 (2850) | 35 (3570) | 56 (5710) | 82 (8360) | 108 (11010) |

| Max. hydr. Pressure (kgf/cm²) | 2.3 (23.5) | 2.8 (29) | 2.7 (28) | 2.5 (26) | 2.6 (27) |

| Max. speed (r.p.m.) min-1 | 8000 | 7000 | 6000 | 5000 | 4200 |

| Thru-hole (diameter) mm | 26 | 33 | 45 | 52 | 75 |

| Standard soft jaw height mm | 23 | 30 | 36 | 38 | 42 |

| Gripping range mm | Φ7-Φ110 | Φ10-Φ135 | Φ13-Φ169 | Φ13-Φ210 | Φ30-Φ254 |

| (with standard soft jaws) kg | 3.8 | 6.1 | 12.5 | 21.9 | 33.7 |

| Matching cylinder | P0928 | P1036 | P1246 F1246S | P1552 F1552S | P1875 F1875S |

DRAWING

1. We are a manufacturer of slant bed cnc lathe machine for 10 years ,Technology in the industry is come

out in front.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Our Advantages and quick delivery, Competitive price ,high quality and long term service to out

customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools

on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can

also according to your need to change the configuration. Thus pls provide us your machining

drawing, we are very glad to design a specific process solution for you and recommend you a

proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong

machine tool research and development capability. We are very willing to offer you customized

highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly

and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the

Equipments for your market ,at the mean time the customers can enjoy the long-term technical

advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term

service to out customers.

Welcome to contact us if need any more information.

Company Features

1. The JSWAY brand is a famous manufacturer of .

2. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has its own production bases, research and development centers as well as technical service centers.

3. We have set up a green team to promote sustainable development. They research new sustainability trends and initiatives, monitor progress in production, so as to guarantee continuous and ongoing improvement in sustainability. We aim to provide quality products and service, shipped on time that meets or exceed our customer's expectations. We will accomplish this end through our commitment to continually improve our quality management system, service, and processes. We will make the business scale double in the next coming years through innovation drive. We will strengthen the R&D ability in offering product diversity.

Q: Can the ice cream, yogurt and K cup be filled and sealed at the same machine?

A: No, it can not be realized at one machine.

Q: Can the filling range be adjusted within a range?

A: Yes.

Q: Do we need to vacuum again after the nitrogen is gone?

A: No, you do not need.

Q: Can the mould, material barrel and filling head be dismantled?

A: Our filling head and barrel are welded and there is no way to remove them.

Q: Do we need add weighing equipment?

A: It can be blanking with measuring cups, screw cutting, no need of weighing equipment.

Q: We need double down the cup and add vibrating tray. Will the coffee powder sprinkle on the rim of the cup to affect the sealing effect?

A: The filling head is extended to the inside of the cup to fill, no coffee powder will be sprinkled on the edge of the cup, and the sealing effect will not be affected.

Q: We want better hygienic conditions and longer shelf-life.

A: We recommend the nitrogen filling function to extend the shelf life.

Q: We need quality assurance.

A: Our machines are exported to many countries, and the health quality has relevant certificates, and has many years of experience in making machines, so that you can rest assured that CE can be seriously sent to customers for reference.

Q: The width of the machine is too large to match our factory building.

A: The size of the machine can be customized as long as it is within reasonable limits.

Q: We want to fill the material of large particles, how to achieve?

A: Large particles are filled with measuring cups, if the powder is screw.

Q: What materials do you use?

A: Material contact parts are 304 stainless steel, if required, 316 stainless steel can also be matched, corrosion resistance.

Q: What are the brands of touch screen, PLC, motor and cylinder?

A: Touch screen: Taiwan Weilun. PLC: Japan 30. Motor: Taiwan Ming Chun. Cylinder: Domestic. (If you need other brands, you can also configure, the price will be a little different.)

Q: How long does it take to produce this machine?

A: About 40 days.