JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

4 axis CNC milling lathe machine with Sauter servo turret SY500/S500/SY300/S300 machining center57

- JSTOMI has excellent customer service management team and professional customer service personnel. We can provide comprehensive, thoughtful, and timely services for customers.

1. JSWAY is carefully designed as per the industry set standards.

2. has good performance and reasonable price.

3. The product has been approved by many international certifications.

4. Installing this product into operation means a range of tasks can be completed faster, freeing up staff to concentrate on other areas of production.

5. The product ensures a high and large production rate. By using this product, more goods are produced in larger quantity and better quality.

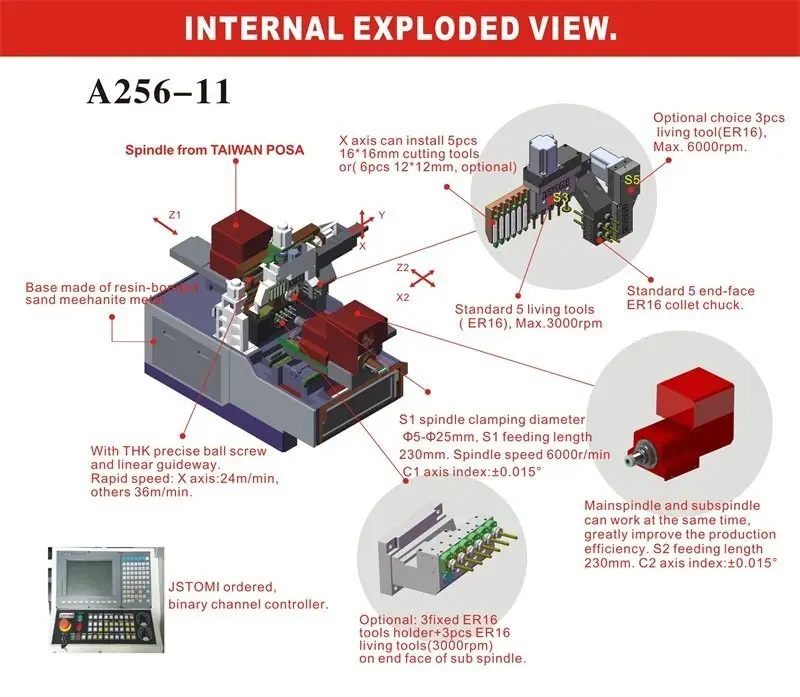

Double Spindle Rotary Auto swiss type CNC Lathe Machine Price

Features:

2. Reduce the frequency of clamping - Enhance Machining Precision

3. Reduce floor area coverage - lower production cost

| Item | A256-11 | |

| Controller | Optional system | Syntec/Fanuc |

Processing Range | Rapid speed | 36m/min(X:24m/min) |

| S1 spindle clamping diameter | φ7-φ35mm | |

| S2 spindle clamping diameter | φ5-φ35mm | |

| S1 spindle max drilling diameter | φ20mm | |

| S1 spindle max tapping diameter | M12 | |

| Max lateral drilling hole diameter | φ10mm | |

| Spindle | S1 S2 spindle power | 4.4KW |

| S1 S2 max speed | 6000rpm | |

| C1 C2 indexing | ±0.015° | |

Spindle Table Stroke | Movable sleeve | 230mm |

| Without sleeve (optional) | S1: 280mm (without sleeve) | |

| Tools | Cutting tools (optional) | 5 tools 16*16 |

| S3 lateral power tools | 5 power tools ER20 | |

| S3 lateral power tools speed | 3000r/min | |

| S3 motor power | 1.0 KW | |

| S4 lateral power tools | 4 fixed ER16 + 4 power tools ER16 | |

| S4 lateral power tools Max speed. | 6000rpm | |

| S4 motor power | 1.0KW | |

| S5 lateral power tools | 5 fixed ER16 + 3 power tools ER16 | |

| S5 max drilling diameter | φ10mm | |

| S5 Max. tapping diameter | M8*P1.25 | |

| S5 lateral tools Max speed | 6000r/min | |

| S5 motor power | 750W | |

| Power | Y1 Z1 servo motor | 850W |

| Z2. X2. Y2 servo motor | 850W | |

| X1 servo motor | 1300W | |

| Dimension | Size( L x W x H ) | 2700*1450*1800mm |

| N.W | 3800KG |

1. We are a manufacturer of slant bed cnc lathe machine for 10 years ,Technology in the industry is come

out in front.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Our Advantages and quick delivery, Competitive price ,high quality and long term service to out

customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. What accuracy can processed work piece reach?

Machining accuracy is very complicated for it can be affected by people, machine, methods, material

and environment, and machine itself is just one of them; besides, accuracy could mean flatness,

verticality, roundness, alignment or position degrees and so on, it’s hard to make it clear in general

concept. Thus pls provide us your machining drawing, we are very glad to design a specific process

solution for you and recommend you a proper cnc machine model.

2. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools on

table.

3. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can also

according to your need to change the configuration. Thus pls provide us your machining drawing,

we are very glad to design a specific process solution for you and recommend you a proper cnc

machine model.

4. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong

machine tool research and development capability. We are very willing to offer you customized

highly-efficient equipment as long as you have certain amount of needs.

5.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly

and efficiently so that can delivered safely to the designated place as guest.

6. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the

Equipments for your market ,at the mean time the customers can enjoy the long-term technical

advisory services in our company.

7. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term

service to out customers.

Welcome to contact us if need any more information.

Company Features

1. In the market, JSWAY acts as the leading supplier.

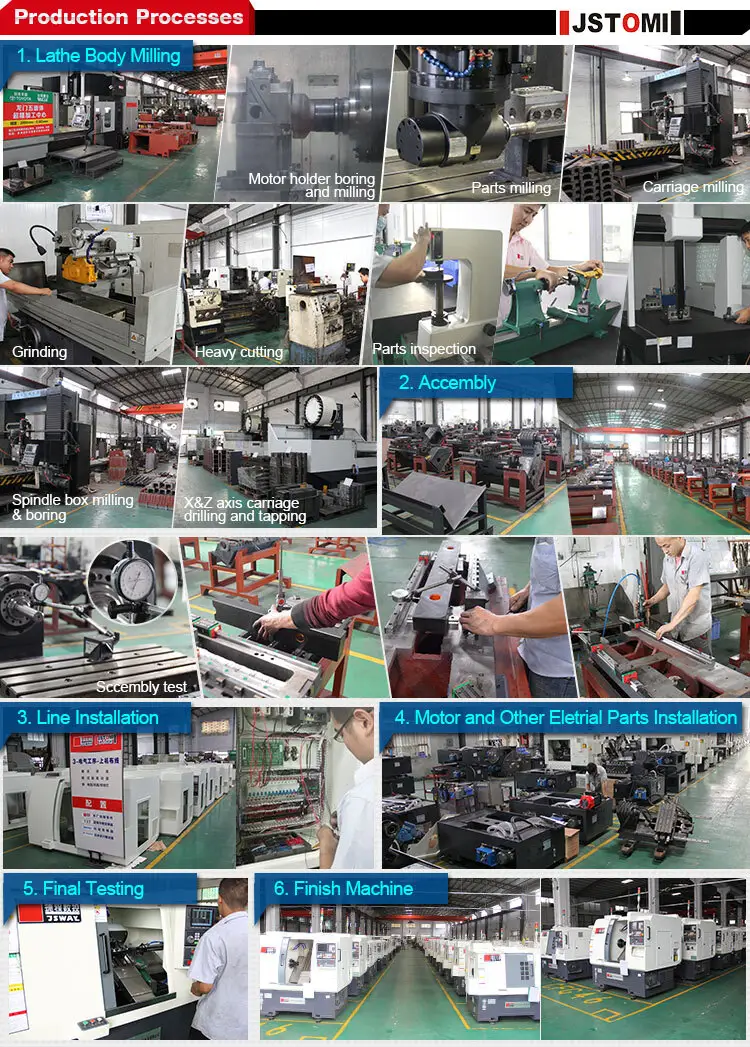

2. We operate advanced manufacturing facilities. Equipped with world-class production lines and machines, they are able to make products that meet the highest standards of quality, precision, and performance.

3. Our corporate culture is to be innovative. That is, to work outside the box, to reject mediocrity, and to never drift along. We work hard to protect and preserve environmental integrity. We incorporate many sustainability plans into each of our production processes, such as reducing waste discharge, save water and electricity, and make full use of resources. We have implemented a sustainability process in our factory. We have decreased energy consumption by investing in new technologies and more efficient facilities.

Tobacco Broyeur Shreder Plastic Bottle Shredder Machine in Philippines

Model | Shreddering Motor Power (kw) | Shreddering Chamber size(mm) |

PNSS-300 | 7.5 | 510×300 |

PNSS-400 | 7.5 | 510×400 |

PNSS-600 | 7.5+7.5 | 510×600 |

PNSS-800 | 18.5+18.5 | 600×800 |

PNSS-1000 | 22+22 | 800×1000 |

PNSS-1200 | 30+30 | 1000×1200 |

PNSS-1400 | 55+55 | 1400×1200 |

PNSS-1600 | 55+55 | 1600×1200 |

PNSS-1800 | 75+75 | 1800×1400 |

PNSS-2000 | 90+90 | 2000×1400 |

| Related Product |

| /Single Shaft Shredder/ |

| Single shaft shredder uses the interaction of movable cutter heads and fixed knives to tear, cut and extrude the material into small size. It can be available for shredding a wide range of materials including plastic, wood, rubber, and paper etc. |

| Learn More |