JSWAY | Leading CNC Lathe Manufacturer & Supplier Since 2007

4 axis CNC milling lathe machine with Sauter servo turret SY500/S500/SY300/S300 machining center10

1. JSWAY is created a unique on a scientific and reasonable basis.

2. has found increasingly wider application due to its advantages of long service life, low coat and .

3. has the advantages of and so on, which has huge fact significance as well as spread worthiness.

4. Our customers can design our and send us drawing to produce.

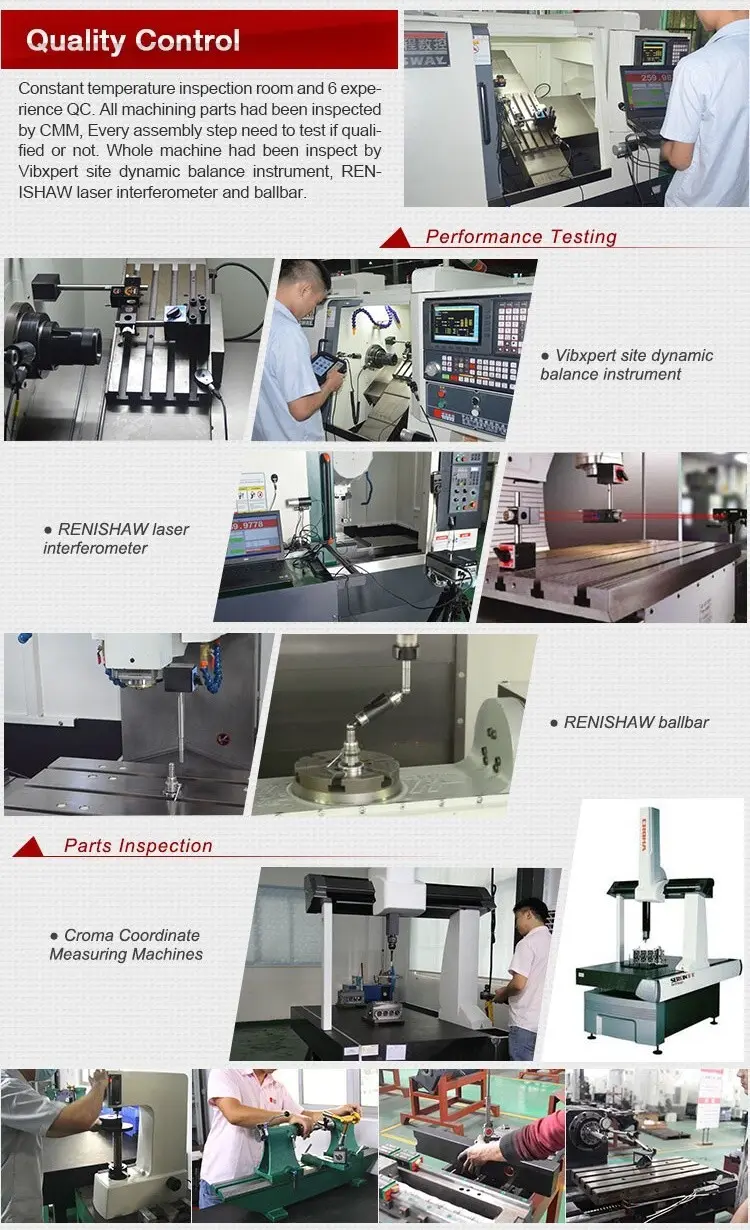

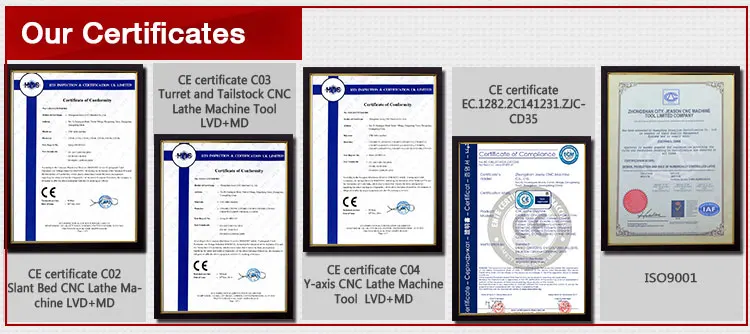

5. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has a complete quality control system.

Features of 5-Axis y-axis cnc lathe machine tool CZG46Y3+2:

1. Y axis have engraving function.

2. This model is for turning, side milling and drilling.

3. Big space for machining, Z/X axis travel is long.

4. Y-axis have 3 living tool and X-axis with 2 tools; X axis can install 5-7 gang tools.

5. Japan gear, low sounds, high precision for Y axis living tool.

6. Spindle with C-axis indexing function.

7. One living power unit on front side.

Technical parameter for 5-axis y-axis cnc lathe machine tool CZG46Y3+2

| NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

| Spindle | TaiWan Posa | A2-5/46 spindle |

| X.Z axis servo motor | Japan YASKAWA | 1300 W |

| Y axis servo motor | Japan YASKAWA | 750 W |

| Spindle servo motor | Japan YASKAWA | 4.4 KW |

| Spindle servo pack | Japan YASKAWA | 5.5 KW |

| Lead screw/lead rail | TaiWan HIWIN/PMI | C3 , level two |

| Bearing | Japan NSK,Germany FAG | P4 level |

| Coupler for lead screw | From Germany | high Precision |

| Parameter | ||

| Capacity | Spindle bore | ¢56 mm |

| Max. material diameter | ¢45 mm | |

| Max. machining diameter | ¢350 mm | |

| Max. length of machining | 180 mm | |

| Max. travel of x-axis | 720 mm | |

| Max. travel of z-axis | 280 mm | |

| Max. travel of Y-axis | 100 mm | |

| Rapid speed (x-axis/z-axis) | 36 m/min | |

| Reposition accuracy | 0.005 mm | |

| Motor | Spindle servo motor | 4.4 KW |

| Spindle speed | 4000 rpm | |

| X/Z-axis servo motor | 1300 W | |

| Y-axis servo motor | 750 W | |

| Servo motor for power unit | 750 W | |

| Tools | Gang type tools | 5--8 |

| Total living power tools unit | 5 | |

| Living tool holder size | ER20/25 | |

| Other | Total power | 7KW |

| Size( L x W x H ) | 2070*1580*1870 | |

| N.W. | 2560 KGS |

Our Service

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can also according to your need to change the configuration. Thus pls provide us your machining drawing, we are very glad to design a specific process solution for you and recommend you a proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong machine tool research and development capability. We are very willing to offer you customized highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the long-term technical advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term service to out customers.

Welcome to contact us if need any more information.

Company Features

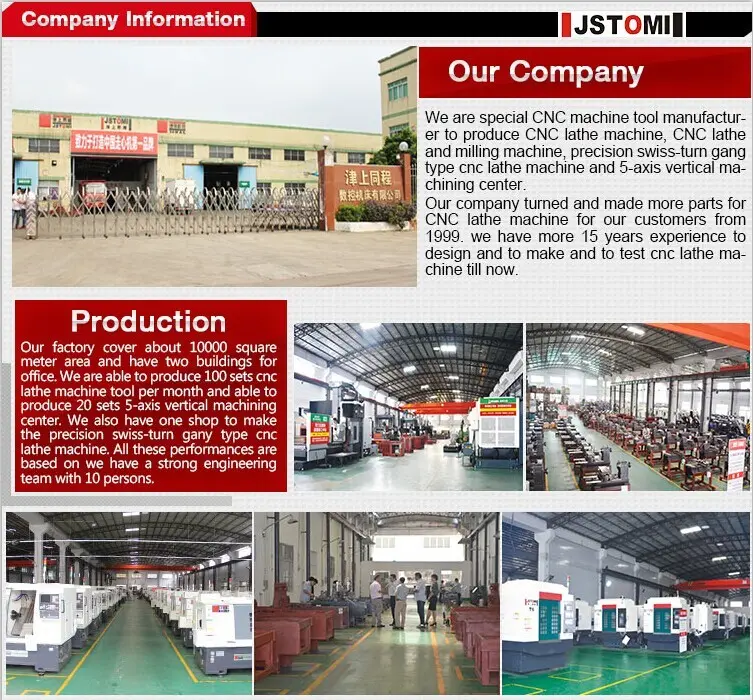

1. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. has strong economic and technological strength in producing . With sales networks spread all over the world, we gradually become one of the leaders in the industry.

2. Due to the efforts of skilled technicians, have become more competitive in this industry.

3. Zhongshan JSTOMI CNC Machine Tool Co., Ltd. is committed to work with customers to achieve a win-win situation. Get an offer! Focusing on cultivating high-level and innovative talents is the assurance for the improvement of JSWAY. Get an offer! It is Zhongshan JSTOMI CNC Machine Tool Co., Ltd. 's mission to continue being the leading company in price-performance ratio as well as customer service. Get an offer! Zhongshan JSTOMI CNC Machine Tool Co., Ltd. seeks long-term developments with our customers to achieve win-win situation. Get an offer!

CDH-1575 -GS

Full Automatic Kitchen Paper Machine

Main Feature:

1.Automatic tension control system, base paper independent frequency conversion motor drive, adapted to different traction base paper

2.Bigger steel embossing roller make embossing clear,Polyurethane embossing roller with good elasticity,long service life

3.Unique gluing composite system, it can produce finished product with color glue,part ofgrain with color.

4.Four pieces of High precision spiral perforated knife roller, the lineup is clear,easy to tear,with low noise

5.Special Suede belt drive system,Adjustment Convenient ,Tightness of the finishedproduct is adjustable

6.Using wallboard structure,make it with Strong rigidity and high stability,

prolong the machine service life

Main Technical Parameter | |

Electric source | 380V, 50Hz, 3 PH |

Finished Roll Diameter | 90-150mm |

Finished Roll Core Diameter | Φ 48 mm |

Raw Material Diameter | ≤Φ 1100 mm (Other sizes can be customized) |

Raw Material Core Diameter | 3”(76.2 mm) (Other sizes are available ) |

Width Of Raw Material | 1750mm, only for producing kitchen paper roll |

GSM of raw paper | 19-25g |

Perforating Pitch | 105~160mm |

Speed | 120-150 meters/min |

Parameter Setting | Touch button LCD Screen operation panel |

Program Controller | Programmable Controller (PLC) |

Mechanism Driving | |

Embossing Roller | Polyurethane embossing roller |

Embossing type | Point to point |

Color unit | Without color printing |

Lamination unit | With lamination |

accumulator | One set |

40 pieces shelves which can be store 20 pieces of finished roll | |

Unwinding Paper Stand | 2 |

Power | Variable frequency speed control, 32KW |

Machine Size | 9500*3100*2200mm(L*W*H) |

Weight | 12000kg |