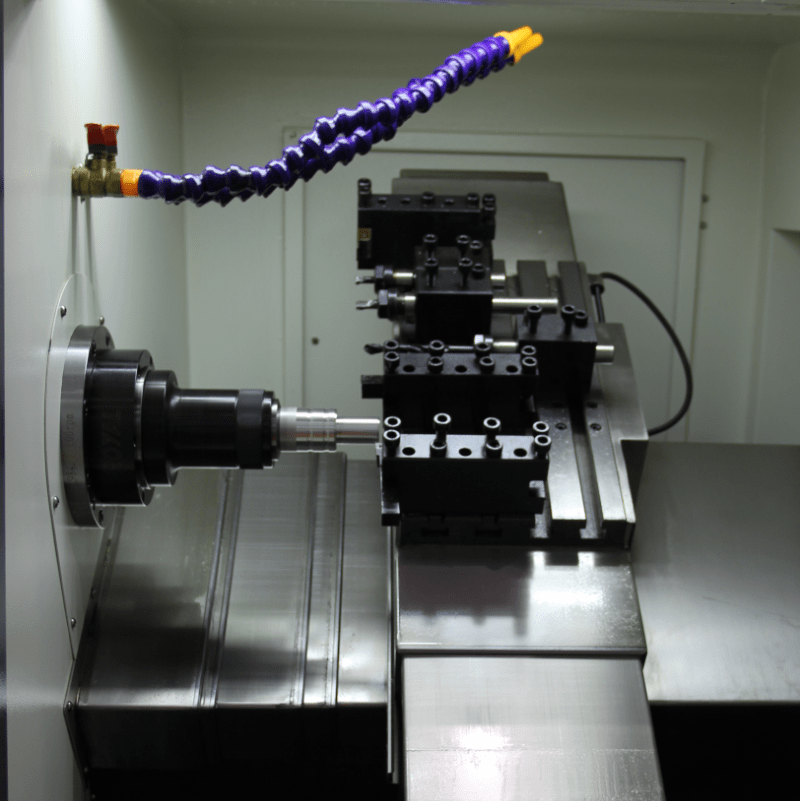

JSWAY gang type cnc lathe machine feature a gang type structure with an inclined bed structure design. These features effectively save tool changing time. The gang tooling system on this lathe machine consists of 2 axis cutting tools mounted on turret. These tools can be indexed and used simultaneously, allowing for faster machining operations and increased productivity. Each tool in the gang tooling system performs specific machining operations such as turning, facing, drilling, or grooving. These gang type CNC Lathes have extraordinary precision and help shop productivity.

The gang type CNC lathe aids with high-speed cutting and holds high accuracy during turning of any part. These CNC Lathes are equipped with linear guides for the X and Y axes to provide stable and accurate cutting. As a standard feature, these machines are equipped with a High Precision C-Axis Indexing function.

Features of 2 axis Gang Type Cnc Lathe CF36

1.The gang type CNC lathe is a versatile machine that offers high accuracy machining while maintaining the same level of precision under both cold and heat conditions.

2.Advanced technology for assembly X-axis and Z-axis. Keep lead rail good performance, so that the gang type CNC lathe machine can achieve high-precision machining accuracy. The X-axis and Z-axis use precision ball screw transmission, which ensures smooth movement and reduces vibration during operation.

3.With a maximum spindle speed of 6000R/M, this gang type cnc lathe is able to achieve high-speed cutting without compromising on accuracy or surface finish quality. Its advanced control system also ensures smooth and precise movements of the cutting tools, resulting in consistent and repeatable results for each part produced.

4. With a rigid bed structure, this gang type cnc lathe can withstand heavy workloads without deforming or losing accuracy.Furthermore, this 2-axis Gang Type Cnc Lathe is equipped with a versatile turret tool holder, allowing for quick tool changes and increasing productivity.

5.The gang type CNC lathe machine is known for its compact design, which makes it suitable for small to medium-sized workpieces. This design often includes a space-saving footprint, efficient chip evacuation, and easy access to the work area for loading and unloading.

Technical parameter for 2 axis gang type CNC lathe machine tool: CF36

NC | TAIWAN/GUANGZHOU | LNC/SYTEC/GSK |

Spindle | TAIWAN POSA | A2-4/36 |

Servo motor | YASKAWAl | 850W |

Spindle motor | SHANGHAI SENLIMA/SFC | 4KW |

Frequency converter | V/T | 5.5KW |

Lead screw | HIWIN/PMI | C3,PⅡlevel |

Bearing | NSK,FAG | P4 level |

Lead screw coupler | MADE IN GERMANY | high precision level |

Parameter | ||

Capacity | Spindle Bore | 46mm |

Max .Meterial Diameter: | 35mm | |

Max Machining Diameter | 280mm | |

Max.Lenght of Machining | 180mm | |

Max. Travel of X-axis | 630mm | |

Max. Travel of Z-axis | 265mm | |

X-axis/Z Fast Moving | 36m/min | |

Reposition Accuracy | 0.005mm | |

Motor | Spindle Motor | 4KW/3.7KW |

Spindle Speed | 6000r/min | |

X-axis Servo Motor | 850W | |

Z-axis Servo Motor | 850W | |

Tools | Gang Type Tools | 5—8 |

LiveTool | No | |

Others | Total Installed Capacity | 6KW |

Size | 1930X1335X1580 | |

N.W. | 2200KG |

Field of application

The 2-axis gang type CNC lathe machine is commonly used in various industries for producing small to medium-sized components with high precision. It is well-suited for tasks such as turning, facing, threading, and drilling operations. Typical applications include aerospace, car accessories, machinery manufacturing, mould, electrical appliances, lighting, communication, plumbing, hardware,furniture, medical instruments, watch, ornaments, e-cigarette and so on. Here are some specific applications of this machine:

1. Automotive Industry: The CNC lathe machine is widely used in the automotive industry for manufacturing components such as crankshafts, pistons, gears, and valve bodies. It enables precise turning and threading operations on these parts, ensuring high-quality and accurate dimensions.

2. Aerospace Industry: In the aerospace industry, the CNC lathe machine is utilized for machining critical components like turbine blades, engine hubs, landing gear components, and hydraulic system parts. The machine's ability to perform precise turning, boring, and threading operations ensures the accuracy and reliability of these aerospace parts.

3. Medical Equipment: The CNC lathe machine is employed to manufacture medical equipment parts like orthopedic implants, surgical instruments, and prosthetics. With its precise machining capabilities, it can produce complex shapes and threads required in these medical components.

4. Electronics Industry: The CNC lathe machine is used in the electronics industry for manufacturing connectors, terminals, and other small precision components. It can accurately machine intricate features, such as threads and grooves, required in these electrical and electronic parts.

5. General Engineering: The 2-axis Gang Type CNC lathe machine is also commonly found in general engineering workshops where a wide range of components are produced. It can handle various materials like steel, aluminum, brass, and plastics, making it suitable for producing parts such as shafts, bushings, pulleys, and fittings.

Our Service

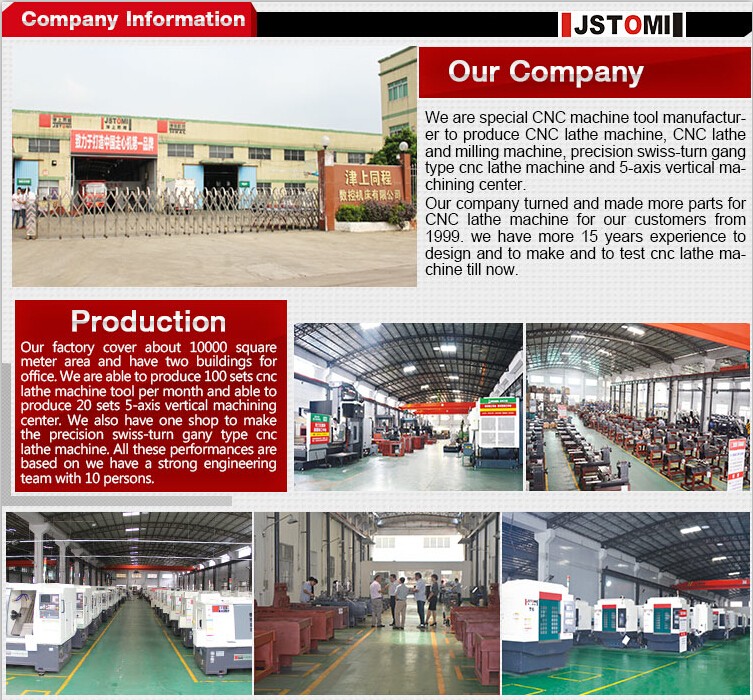

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools on table.

2. How to choose the best fit for your gang type cnc machine?

Machining Requirements: Evaluate your specific machining requirements, including the size, complexity, and material of the parts you intend to produce. Consider factors like maximum turning diameter, maximum machining length, chuck size, and spindle power. Ensure that the machine's capacity meets your production needs.

Axis Configuration: Determine the number of axes you require based on the complexity of the parts. While a 2-axis machine is suitable for simple operations, more complex parts may require additional axes, such as a live tooling turret or a sub-spindle.

Gang Tooling System: Consider the number of tool positions available in the gang tooling system. The more tool positions, the greater flexibility and variety of operations you can perform simultaneously. Evaluate the tooling system's indexing capability and compatibility with your specific tooling needs.

CNC Control System: Assess the features and capabilities of the CNC control system. Look for user-friendly interfaces, programming options, and compatibility with CAD/CAM software. This ensures efficient programming, ease of operation, and seamless integration into your existing manufacturing processes.

Precision and Accuracy: Check the machine's specifications for precision and accuracy. Look for features like high-resolution linear scales, rigid construction, and robust spindle design. These factors contribute to the machine's ability to achieve tight tolerances and consistent machining results.

Machine Durability and Reliability: Consider the build quality, reputation, and reliability of the machine manufacturer. Look for machines constructed with high-quality materials and components that can withstand heavy usage and provide long-term reliability.

3. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term service to out customers.

Welcome to contact us if need any more information.

Copyright © 2018 Guangdong JSWAY CNC Machine Tool Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.