Contact Us

TEL.: 0086-760-22185850

Contact Person: Mr. Xiang

E-mail: sales@jswaymachinetool.com

13326901601@163.com

Whatapp/ Wechat/ Skype:

0086-19966351138

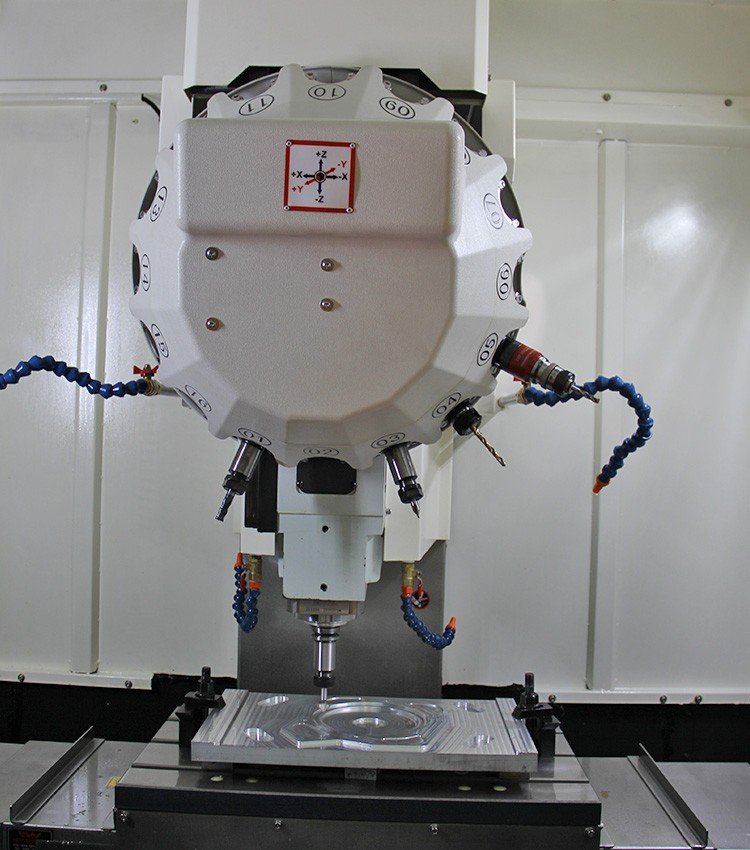

Vertical CNC drilling machine is a precision machining tool specifically designed for carrying out drilling operations with high accuracy and efficiency.

Introduction

|  |

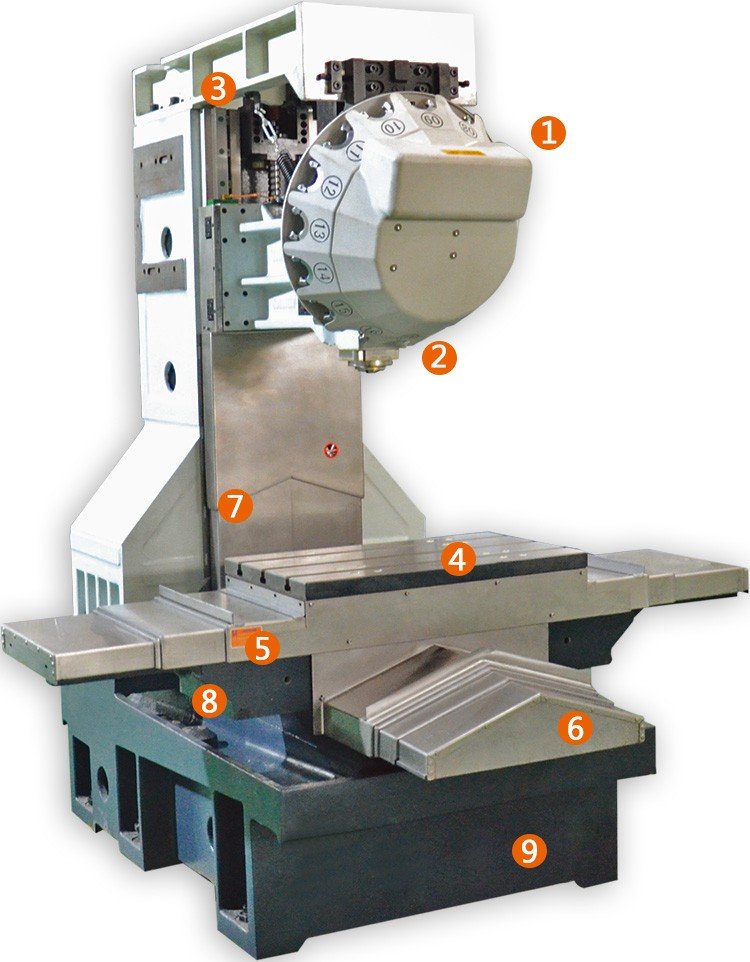

| 1.motor drive the spindle directly so that there will not produce any noise of the belt and wheel gear,and also the problem of shaking ,imprve smoothness of surface,can get a high efficiency rigid tapping. 2.this machine adopt RAYOL spindle ,can satisfy the inquiry of speed and rigid. increase stability of stand column . 4.3 axis adopt high precision guideway ( 35mm ) from taiwan,can hold a heavy load ,rapid speed,ensure precise localization. 5.ballscraw use structure of prestretching and prepressing ,so this machine own a high rigidity and extend accuracy life. 6.wider A type stand column ensure the stability of machine . 7.Receding stampings type base design, collocation more water tank, double pump can rapid clearance stampings, avoid the machine internal chips. |

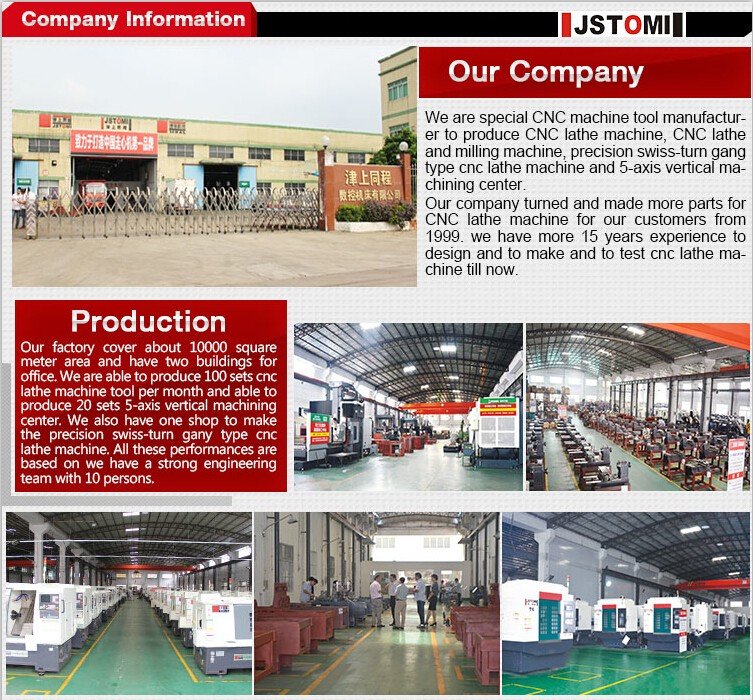

Specialized in manufacturing, innovation excellence

Feature:

1. Auto tool changer system made by Taiwan Sanjet.

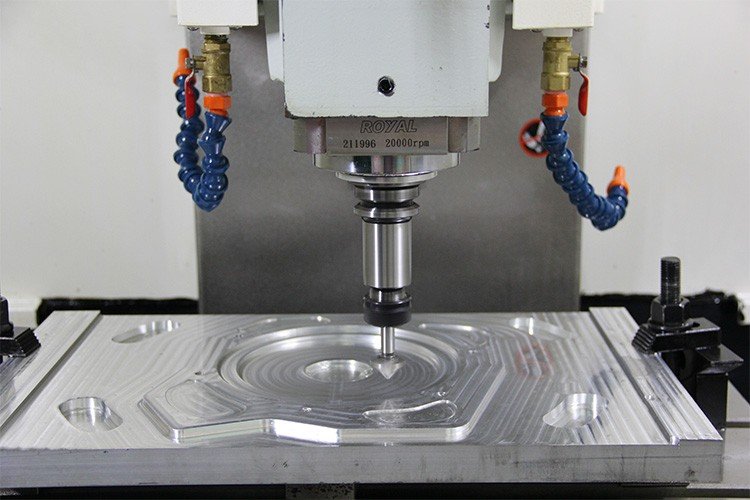

2. Taiwan Royal spindle. Max speed up to 20000rpm, can make smooth finish.

3.Full cover shell, steel slide cover.

4. Owned 4th axis function, customer can add it according to their demand (no extra cost).

5.Rapid moving speed up to 60m/min.

6. All spindle had been strictly test by PRUFTECHNIK :dynamical balance testing instrument

(Made in German).

7.Double linkage door is so wide for material load and unload.

8. X/Y/Z axis had been inspect by Renishaw( Made in England) ball-bar and laser interferometer.

Advantage of vertical cnc drilling machine

Vertical drilling machining center is a specialized machine tool used for precision drilling, tapping, and other related operations in a variety of materials. Here are some key features and benefits of a vertical drilling machining center:

Vertical Orientation: The vertical design of the Vertical Cnc Drilling Machine allows for easy loading and unloading of workpieces, making it suitable for a wide range of part sizes and geometries.

Multi-axis Capabilities: Many vertical drilling machining centers feature multi-axis functionality, enabling complex drilling and milling operations to be performed in a single setup.

High Precision: Vertical cnc drilling machine offer high precision and accuracy, crucial for creating intricate patterns, holes, and features with tight tolerances.

Versatility: In addition to drilling, these machining centers can often perform a variety of other tasks, such as tapping, reaming, countersinking, and counterboring.

Efficiency and Productivity: With automated tool changers and advanced CNC control systems, vertical drilling machining centers can optimize production processes, reducing setup times and increasing overall productivity.

Customization: The flexibility of vertical cnc drilling machine allows for the production of custom parts and components tailored to specific design requirements.

Suitable for Various Industries: Vertical drilling machining centers find applications in industries such as aerospace, automotive, mold making, and general manufacturing, where precise hole-making and machining are essential.

Integration with CAD/CAM Software: Integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) software enables seamless programming and execution of complex machining tasks.

By combining precision, versatility, and efficiency, a vertical drilling machining center provides a reliable solution for a wide range of drilling and related machining operations. Whether you're producing prototypes or mass-manufacturing components, this machine offers the capabilities needed to meet your machining requirements.

| T6 vertical cnc drilling machine | ||||

| Controller | MITSUBISHI-M70 | SIEMENS828 | FANUC | |

| X/Y axis servo motor | 1.5KW | 2.29KW | 1.6KW | |

| Z axis servo motor | 3.0KW | 3.14KW | 2.7KW | |

| spindle motor | 5.5KW | 4.8KW | 5.5KW | |

| Linear guide way | Hiwin PMI | |||

| Bearing | NSK/FAG | |||

| Couoling | From Germany/Taiwan | |||

| spindle | Taiwan Royal/RuiYing | |||

| NC | MITSUBISHI/FANUC/SIEMENS828 | |||

| Travel | max. travel of x-axis | 600 mm | ||

| max. travel of y-axis | 400 mm | |||

| max. travel of z-axis | 300 mm | |||

| distance between table and spindle nose | 155-320/400 mm | |||

| Table | table size | 700x420 | ||

| Max load | 300kg | |||

| spindle | spindle speed | 20000 rpm | ||

| max tapping speed | 4500rpm | |||

| spindle taper | BT40 | |||

| Feeding speed | Repid speed | 60m/min | ||

| cutting speed | X/Y/Z 1~30000(mm/min) | |||

| Tools | tools size | MAS-BT40 | ||

| Max tools storage | 24 | |||

| Max. tool length | 250mm | |||

| Max tools diameter | 110mm | |||

| Max. tools weight | 3KG/pc | |||

| tools changing time | 1.4s | |||

| Other | Power voltage | AC380V 50/60Hz | ||

| air pressure | 0.65Mpa | |||

| air flow | 45 L/min | |||

| machine hight | 2500mm | |||

| floor area | 1.900*2.680 m | |||

| G.W | 3.8T | |||

| accuracy of two axis | ‹0.004mm | |||

| repositioning of tww axis | ‹0.004mm | |||

Our Service

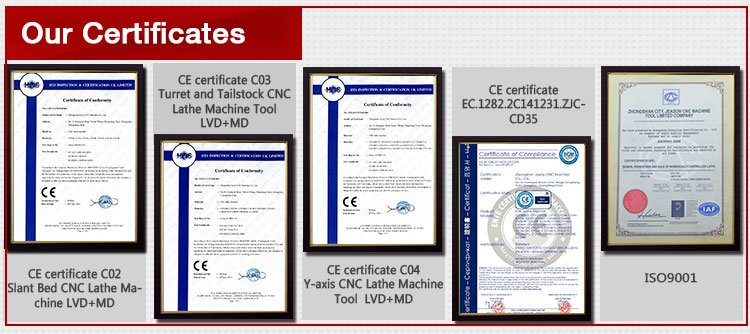

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front

in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements of

guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools on

table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can also

according to your need to change the configuration. Thus pls provide us your machining drawing,

we are very glad to design a specific process solution for you and recommend you a proper cnc

machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong machine

tool research and development capability. We are very willing to offer you customized highly-efficient

equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the Equipments

for your market ,at the mean time the customers can enjoy the long-term technical advisory services

in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements of guests.

Our Advantages and quick delivery, Competitive price ,high quality and long term service to out customers.

Welcome to contact us if need any more information.

Copyright © 2018 Guangdong JSWAY CNC Machine Tool Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.