A 4-axis CNC lathe machine with a lateral power tool is a highly advanced machining solution that provides exceptional capabilities for complex and precision manufacturing. This configuration allows for simultaneous machining operations on multiple surfaces of a workpiece, enabling the creation of intricate geometries and profiles. With the inclusion of a lateral power tool, off-center and angled machining tasks can be easily performed, expanding the range of possible operations. Ideal for industries that demand high-precision components, such as aerospace, automotive, and medical device manufacturing, this setup offers superior flexibility and efficiency in multi-axis machining. Experience the next level of manufacturing performance with a 4-axis CNC lathe machine equipped with a lateral power tool.

Feature

1.C Axis have indexing function. Can put on 1 live tool

2.Own hi-tech installation technology, no hurt to lead rail

3.Fast machining speed up to 36m/min

4.High cost and working performance

5.Can install power tool on Z axis for machining square/hexgonal parts

6.Lining tool max speed up to 4500rpm

Advantage

4 Axis CNC Lathe Machine with a lateral power tool offers several advantages over traditional machining solutions:

Multi-Axis Machining: The addition of the fourth axis and lateral power tool enables the machine to perform complex and multi-sided machining operations in a single setup, reducing the need for multiple workholding and tool changeovers.

Increased Flexibility: The lateral power tool allows for off-center and angled machining, providing the ability to create more intricate geometries and features that would be challenging to produce using conventional methods.

Reduced Setup Time: With the ability to perform multiple operations in a single setup, the 4-axis CNC lathe machine with a lateral power tool significantly reduces setup time, resulting in improved productivity and efficiency.

Enhanced Precision: The multi-axis capabilities of the machine allow for precise control over tool movements, leading to higher accuracy in machining complex parts and components.

Expanded Machining Capabilities: The lateral power tool opens up the possibility for additional operations such as milling, drilling, and tapping, further expanding the range of achievable machining processes.

Improved Surface Finish: The ability to perform multi-axis machining with a lateral power tool can result in superior surface finishes and overall part quality due to reduced handling and repositioning requirements.

Overall, the 4 Axis CNC Lathe Machine with a lateral power tool offers enhanced capabilities for complex machining tasks, increased productivity, and the ability to produce high-precision components with greater efficiency compared to conventional machining methods.

Technical parameter

CONFGURATION | ||

NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

Spindle | TAIWAN POSA | A2-4/36 |

Servo motor | YASKAWA | 850W |

Spindle motor | YASKAWA | 4.4KW |

Servo pack | YASKAWA | 5.5KW |

Lead screw | HIWIN/PMI | C3,PⅡ level |

Bearing | NSK,FAG | P4 level |

Lead screw coupler | MADE IN TAIWAN | high precision level |

PARAMETER | ||

Capacity | Spindle bore | 46mm |

Max.meterial diameter: | 36 mm | |

Max machining diameter | 280mm | |

Max.lenght of machining | 180mm | |

Max. travel of X-axis | 630mm | |

Max. travel of Z-axis | 265mm | |

X-axis/Z fast moving | 36m/min | |

Reposition accuracy | 0.005mm | |

Motor | Frequency motor | 4.4KW |

Spindle speed | 3000r/min | |

X-axis servo motor | 850W | |

Z-axis servo motor | 850W | |

Tools | Gang type tools | 5--8 |

Live tool | 1 | |

Others | Total installed capacity | 5KW |

Size | 1930X1335X1580 | |

N.W. | 2200KG |

Our Service

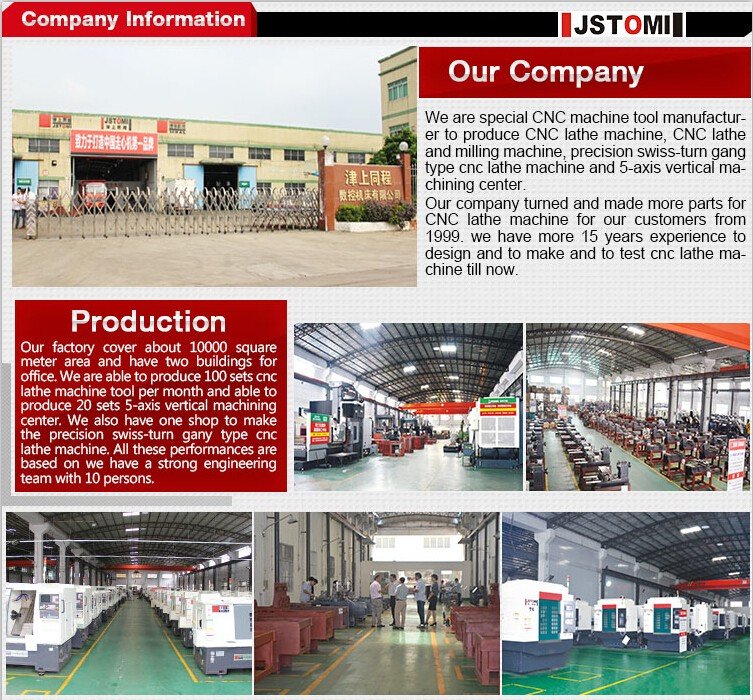

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front

in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,

2-3 tools on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,

We can also according to your need to change the configuration. Thus pls provide us your

machining drawing, we are very glad to design a specific process solution for you and

recommend you a proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and

strong machine tool research and development capability. We are very willing to offer you

customized highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more

quickly and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy

all the Equipments for your market ,at the mean time the customers can enjoy the long-term

technical advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term service

to out customers.

Welcome to contact us if need any more information.

Copyright © 2018 Guangdong JSWAY CNC Machine Tool Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.