|

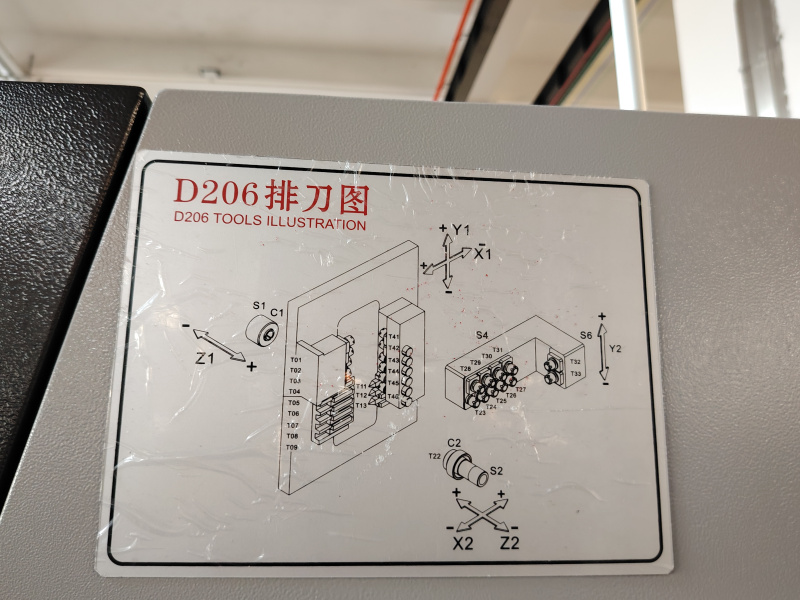

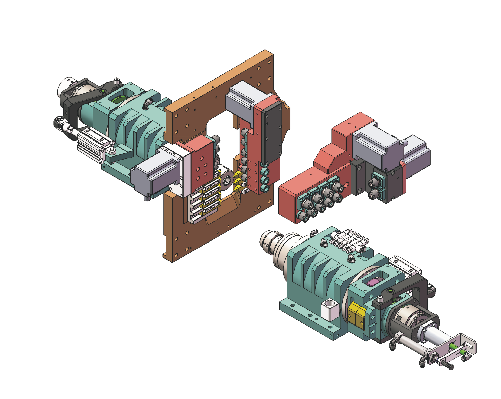

1. With six axes of motion, including X, Y, Z, C, and additional live tooling axes, the 6 axis Swiss lathe offers multi-tasking capabilities, enabling a wide range of complex machining operations in a single setup.

2. The machine's design and construction, coupled with advanced control systems, ensure precise and accurate machining, resulting in tight tolerances and high-quality surface finishes.

3. The dual-spindle, multi-axis configuration enables the seamless production of complex parts, reducing lead times and enhancing overall productivity.

4. The inclusion of two electric spindles allows for simultaneous machining operations on the front and back of the workpiece, reducing cycle times and increasing production efficiency.

Advantage

| Item | D206C | D206D | |

| Controller | Optional system | JSTOMI ordered system | JSTOMI ordered system |

Processing Range | Rapid speed | 30m/min(X:24m/min) | 30m/min(X:24m/min) |

| S1 spindle clamping diameter | φ7-φ23mm | φ7-φ23mm | |

| S2 spindle clamping diameter | φ5-φ20mm | φ5-φ20mm | |

| S1 spindle max drilling diameter | φ10mm | φ10mm | |

| S1 spindle max tapping diameter | M8 | M8 | |

| Max lateral drilling hole diameter | φ8mm | φ8mm | |

| Spindle | S1 S2 spindle power | 7.5KW | 7.5KW |

| S1 S2 max speed | 10000rpm | 10000rpm | |

| C1 C2 indexing | ±0.015° | ±0.015° | |

Spindle Table Stroke | Movable sleeve | 80mm | 80mm |

| Without sleeve (optional) | S1: 230mm (without sleeve) | S1: 230mm (without sleeve) | |

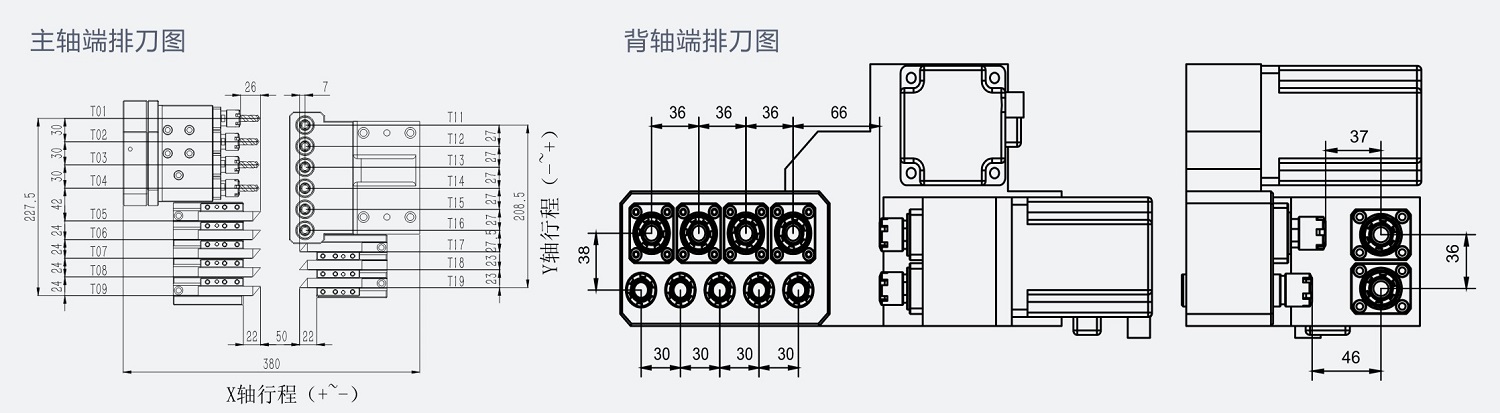

| Tools | Cutting tools (optional) | 5+3 tools 12*12 | 5+3 tools 12*12 |

| S3 lateral power tools | 2power tools ER16+2 fixed | 2power tools ER16+2 fixed | |

| S3 lateral power tools speed | 6000r/min | 6000r/min | |

| S3 motor power | 1.0 KW | 1.0 KW | |

| S4 lateral power tools | 4 fixed ER16 + 4 power tools ER16 | 4 fixed ER16 + 4 power tools ER16 | |

| S4 lateral power tools Max speed. | 6000rpm | 6000rpm | |

| S4 motor power | 1.0KW | 1.0KW | |

| S5 lateral power tools | / | 4 fixed ER16 + 2 power tools ER16 | |

| S5 max drilling diameter | / | φ10mm | |

| S5 Max. tapping diameter | / | M8*P1.25 | |

| S5 lateral tools Max speed | / | 6000r/min | |

| S5 motor power | / | 750W | |

| Power | Y1 Z1 servo motor | 850W | 850W |

| Z2. X2. Y2 servo motor | 850W | 850W | |

| X1 servo motor | 1300W | 1300W | |

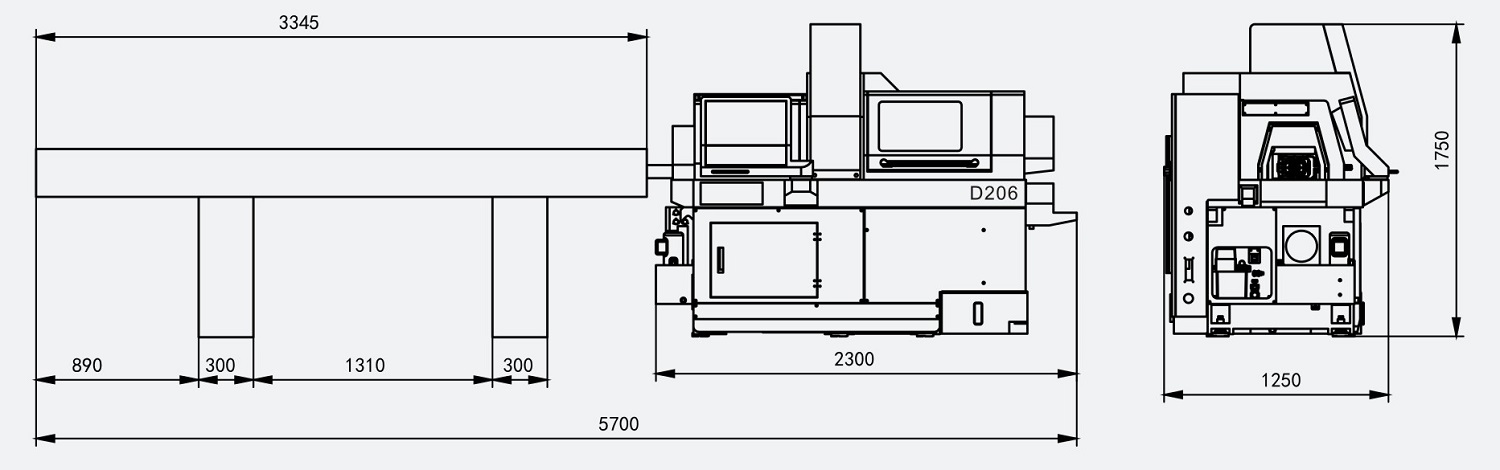

| Dimension | Size( L x W x H ) | 2700*1450*1800mm | 2700*1450*1800mm |

| N.W | 3800KG | 3800KG |

|  |

Welcome to contact us if need any more information.

Copyright © 2018 Guangdong JSWAY CNC Machine Tool Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.