The 2 axis cnc lathe machine with slant bed turret and tailstock is designed to revolutionize the world of machining, this cutting-edge machine employs advanced computer numerical control technology to deliver unparalleled accuracy and productivity. The slant bed design enhances stability during operation while providing easy access to the workpiece for quick setup and efficient tool changes. Equipped with a robust turret system, it allows for multiple tools to be mounted simultaneously, enabling seamless transitions between different operations without any manual intervention. Additionally, the inclusion of a tailstock further expands its capabilities by providing additional support for long or heavy workpieces during turning processes. With its two-axis control system, operators have full command over the X and Z axes movements, allowing for intricate turning operations with utmost precision.

Core product advantages

A slant bed 2-axis CNC lathe machine with turret and a tailstock offers enhanced capabilities for machining operations. Here are some key features and benefits of this configuration:

Slant Bed Design: The slant bed design improves the rigidity and stability of the machine, allowing for better cutting performance and accuracy. It helps in reducing vibration and improving chip flow during machining, resulting in improved surface finish and dimensional accuracy of the machined parts.

Turret with Multiple Tool Positions: The turret on the machine provides a quick tool change capability, allowing for efficient machining of complex parts with multiple cutting operations. With a range of tool positions available, you can set up different cutting tools simultaneously, reducing overall machining time and increasing productivity.

Tailstock Functionality: The inclusion of a tailstock adds versatility to the machine. The tailstock supports long and slender workpieces, providing additional stability during machining operations. It enables operations such as drilling, reaming, and tapping on the end face of the workpiece, expanding the range of parts that can be produced with the machine.

Turning and Threading Operations: The 2-axis configuration allows for turning operations, including external and internal turning, facing, grooving, and chamfering. Additionally, the machine can perform threading operations such as single-point threading and thread chasing, producing accurate and precise threads on the workpiece.

Accurate Machining: The combination of a slant bed, turret, and tailstock ensures accurate machining results. The slant bed provides excellent thermal stability, minimizing thermal deformations during machining. The turret's tool positioning and indexing accuracy allow for precise cutting operations, while the tailstock provides additional support for maintaining part accuracy during machining.

Compact Footprint: The slant bed design and compact construction of the machine optimize space utilization in your workshop. This makes it suitable for manufacturing facilities with limited floor space.

Ease of Programming: The machine is equipped with a CNC control system that offers user-friendly programming interfaces. This simplifies the setup and operation of the machine, minimizes programming errors, and allows for efficient production planning and optimization.

Versatile Applications: A 2-axis CNC lathe machine with a slant bed turret and tailstock can be used for various applications in industries like automotive, aerospace, medical, and general engineering. It can produce a wide range of components, including shafts, bolts, bushings, cylinders, and other rotational parts.

By incorporating the advantages of a slant bed design, turret tooling system, and tailstock functionality, this type of CNC lathe machine provides enhanced machining capabilities, improved accuracy, and versatility for a variety of turning and threading applications.

JSWAY CNC 2-Axis slant bed lathe combines proven machine design with advance technology in control and manufacturing. Reliability and stability make these a favorite among demanding job shops and in-house productions alike. The turret and rigid machine body structure enable higher turning efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around.

Up to 15″ 3-jaw chuck with 5.15″ bar capacity

Up to 52mm max turning diameter and 350mm max turning length

High speed / high accuracy turret

Induction hardened and precision ground box ways

High grade precision ball screws and pretension for enhanced precision

Machine parameter

PARAMETER | |||||

| CB46DW | CB56DW | CL46DW | CL56DW | |

NC | TAIWAN | LNC/SYNTEC/GSK | |||

CAPACITY | spindle bore | Φ56 mm | Φ66 mm | Φ56 mm | Φ66 mm |

max. material diameter | Φ45 mm | Φ52mm | Φ45 mm | Φ52 mm | |

max. machining diameter | Φ350 mm | Φ350 mm | Φ350 mm | Φ350 mm | |

max. length of machining | 350 mm | 350 mm | 550 mm | 550 mm | |

max. travel of x-axis | 250 mm | 250 mm | 250 mm | 250 mm | |

max. travel of z-axis | 380 mm | 380 mm | 580 mm | 580 mm | |

rapid speed (x-axis/z-axis) | 30 m/min | 30 m/min | 30 m/min | 30m/min | |

reposition accuracy | 0.005 mm | 0.005 mm | 0.005 mm | 0.005 mm | |

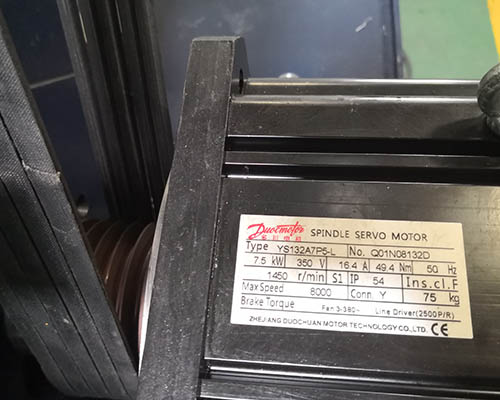

MOTOR | spindle variable frequency motor | 7.5KW | 11KW | 7.5KW | 11KW |

Max spindle speed | 4500 rpm | 3000 rpm | 4500 rpm | 3000 rpm | |

x-axis servo motor | 1300 W | 1300 W | 1300 W | 1300 W | |

z-axis servo motor | 1300 W | 1300 W | 1300 W | 1300 W | |

TOOLS | Turret | 8-12 | 8-12 | 8-12 | 8-12 |

TAILSTOCK | tailstock travel | 380 mm | 380 mm | 580 mm | 580 mm |

thimble travel | 100 mm | 100 mm | 100 mm | 100 mm | |

thimble taper | MT4 | MT4 | MT4 | MT4 | |

diameter of tailstock | Φ72 mm | Φ72 mm | Φ72 mm | Φ72 mm | |

OTHER | total power | 12 KW | 14 KW | 12 KW | 14 KW |

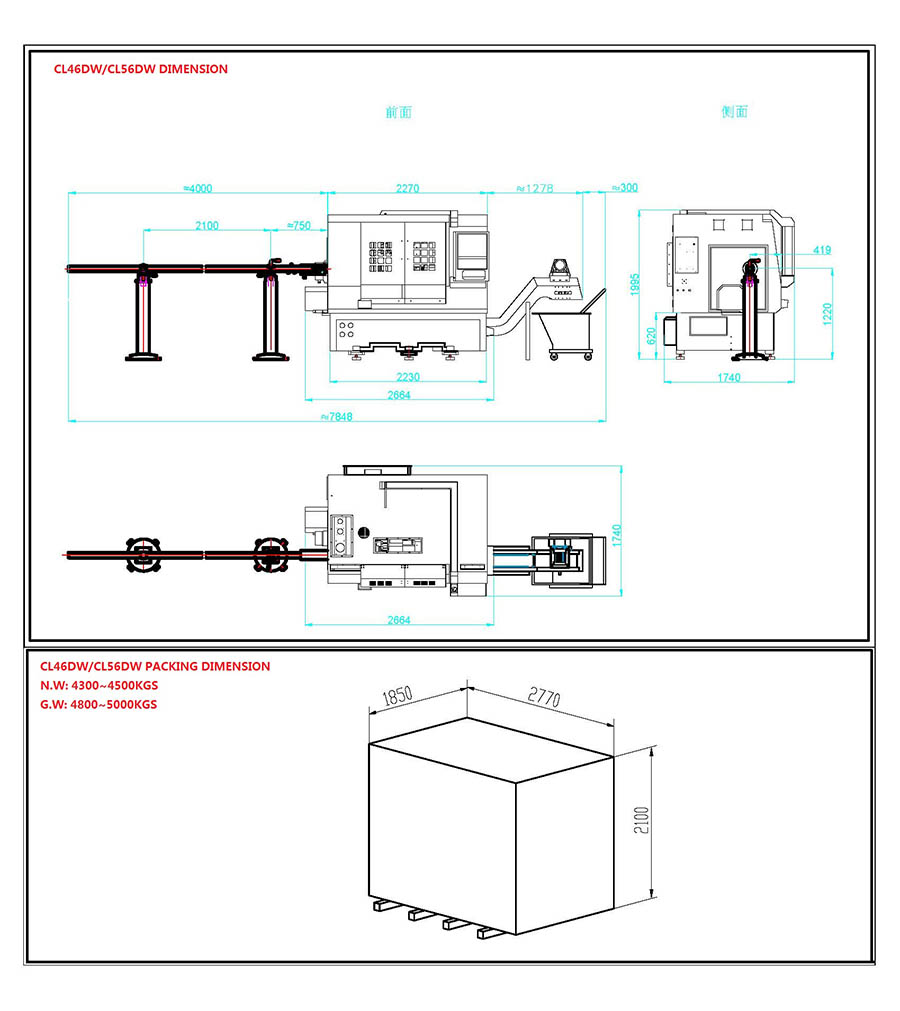

size(mm x mm x mm) | 2300×1650×1800 | 2300×1650×1800 | 2500×1500×1950 | 2500×1500×1950 | |

N.W. | 4000 KGS | 4300 KGS | 4000 KGS | 4300 KGS | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CB46DW | CB56DW | CB46DW | CB56DW | |

COLLET | 4-45mm | 4-52 | 5-350mm | 5-350mm |

CHUCK | 4-300mm | 4-300mm | 5-340mm | 5-340mm |

MACHINING RANGE | ||||

| Diameter | Length | ||

CL46DW | CL56DW | CL46DW | CL56DW | |

COLLET | 4-45mm | 4-52 | 5-550mm | 5-550mm |

CHUCK | 4-280mm | 4-280mm | 5-540mm | 5-540mm |

Details of the figure

Copyright © 2018 Guangdong JSWAY CNC Machine Tool Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.