Core product advantages

Machine parameter

PARAMETER | |||

|

| CZG46D | CZG56D |

CAPACITY | Spindle bore | 56MM | 66 MM |

Max. material diameter: | 45MM | 52 MM | |

Max swing over bed | 350MM | 350mm | |

Max.lenght of machining | 100MM | 100 mm | |

Max. travel of X-axis | 720MM | 720 mm | |

Max. travel of Z-axis | 280MM | 280 mm | |

X-axis/Z fast moving | 30 M/MIN | 30 m/min | |

Reposition accuracy ( x/z) | x≤0.007 mm z≤0.015 mm | x≤0.007 mm z≤0.015 mm | |

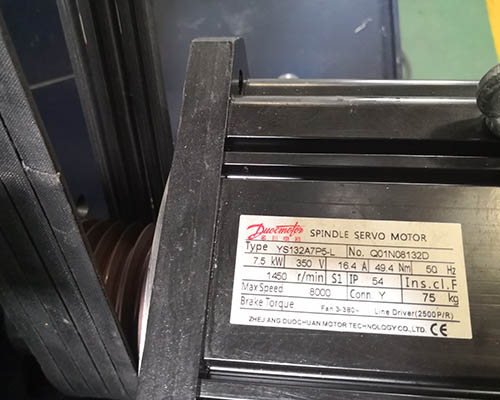

MOTOR | Servo motor | 7.5KW | 7.5KW |

Spindle speed | 4500R/MIN | 3000 rpm/min | |

X-axis servo motor | 1.3KW | 1.3KW | |

Z-axis servo motor | 1.3KW | 1.3KW | |

TOOLS | Turret | 8+3 | 8+3 |

OTHERS

| Total installed capacity | 9 KW | 13 KW |

Size | 2025X1385X1910 | 2025X1385X1910 | |

N.W. | 2700KG | 2750KG | |

MACHINING RANGE | ||||

| Diameter | Length | ||

CZG46D | CZG56D | CZG46D | CZG56D | |

COLLET | 4-45mm | 4-52 | 5-100mm | 5-80mm |

CHUCK | 4-140mm | 4-160mm | 5-100mm | 5-80mm |

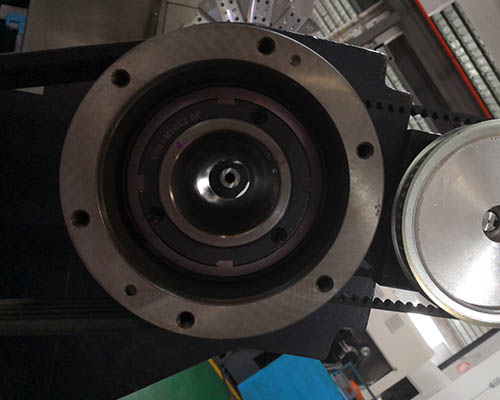

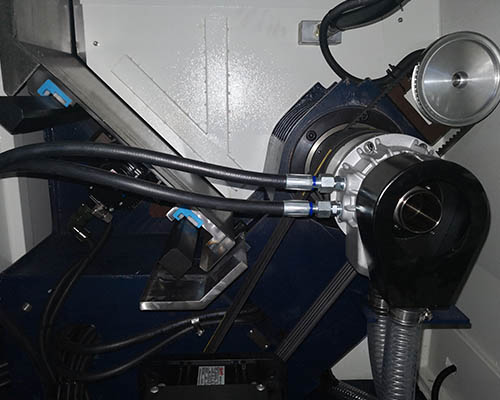

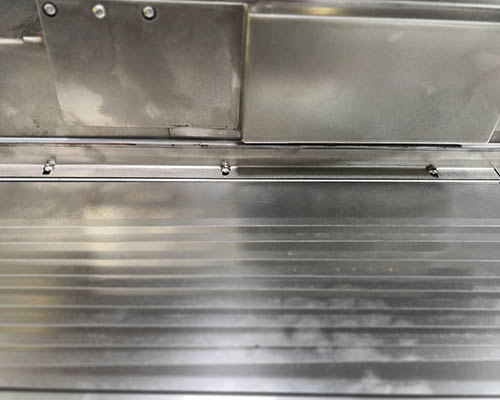

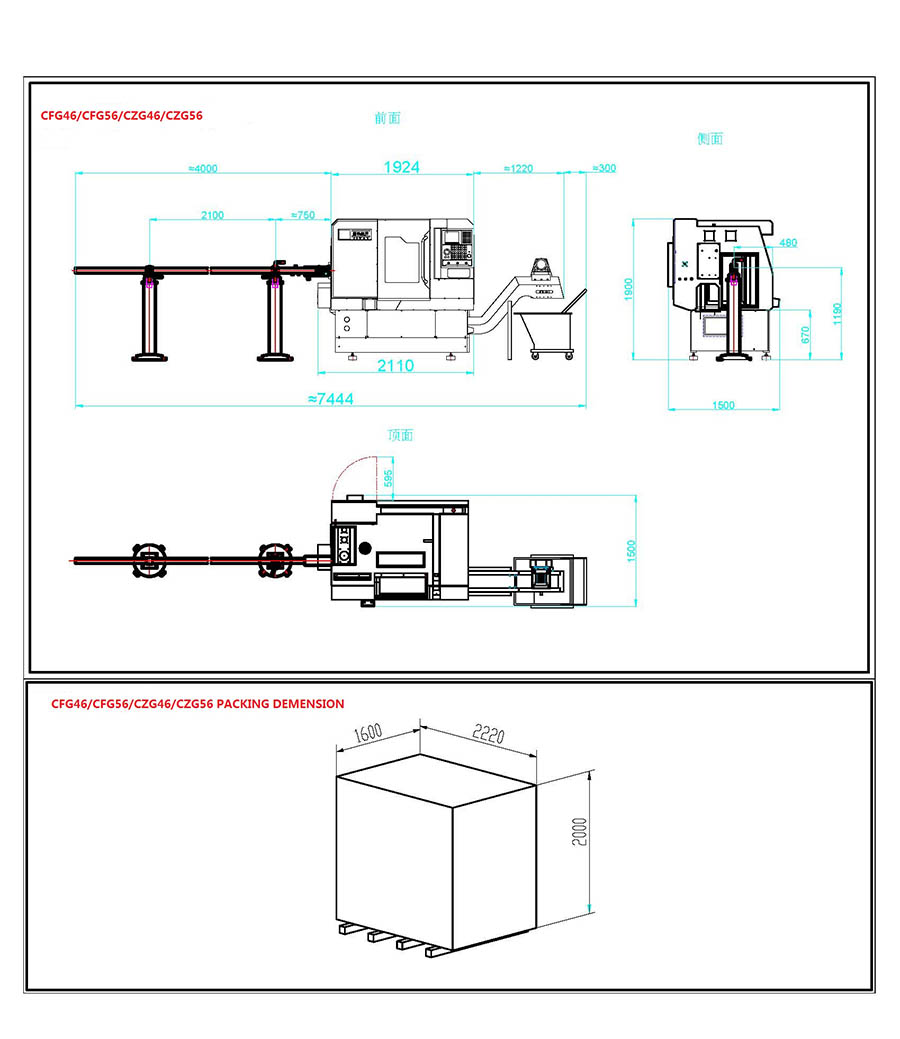

Details of the figure

Packing and Shipping

This machine is widely use in LED parts, smart phone parts, precision industrial, hydraulic parts, E-cigarettes, optical parts, Valve accessory, medical devices and aviation industrial.

Contact us and get two collect chuck for free!

Write down your company information, and confirm the order, you will get two more collet chuck!

Machine dimension and packing dimension

Copyright © 2018 Guangdong JSWAY CNC Machine Tool Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.