Y-axis CNC lathe machine is a type of computer numerical control (CNC) machine tool that features a Y-axis slide for movement in the vertical direction, in addition to the traditional X and Z axes. This feature enables the machine to perform off-center milling operations on cylindrical workpieces. JSWAT y axis cnc lathe combine ±2" of Y-axis travel, full C-axis motion, and high-performance live tooling to create versatile done-in-one machining solutions for any shop. Easily perform secondary milling operations on your lathe – such as off-center milling, drilling, and tapping – to boost throughput and increase accuracy.

|  |

| The Y-axis CNC lathe machine has all the capabilities of a traditional lathe, with the added advantage of a Y-axis slide for off-center milling and drilling operations. This makes it a versatile machine tool for a variety of turning and milling applications. | the y axis cnc lathe machine can perform a wide range of machining operations, including turning, drilling, milling, and tapping. This versatility allows manufacturers to produce a variety of parts using a single machine, reducing the need for multiple machines and setups. |

5 Axis CNC Lathe Factory Y Axis CNC Lathe Machine

Features

1. Y axis have engraving function.

2. This model is for turning, side milling and drilling.

3. Big space for machining, Z/X axis travel is long.

4. Y axis and X axis have 2 living tooleach; X axis can install 3-5 gang tools.

5. Japan gear, low sounds, high precision for Y axis living tool.

6. Spindle with C-axis indexing function.

7. Base and the slanting bed is one piece.

8. living tool max speed is 4500rpm.

Advantage

1. Increased Machining Flexibility: The addition of the Y-axis allows for off-center and angled machining operations, expanding the range of possible geometries that can be machined. It enables the creation of complex features such as off-center drilled holes, angled grooves, and slanted surfaces.

2. Simultaneous Machining: The Y-axis enables simultaneous machining on multiple surfaces of a workpiece, reducing production time and increasing efficiency. This capability is particularly useful when machining parts with intricate designs or when performing multitasking operations.

3. Improved Accuracy and Surface Finish: The Y-axis enhances the accuracy and surface finish of machined parts by enabling precise control over tool movements in multiple directions. This is especially beneficial for applications that require tight tolerances and high-quality surface finishes.

4. Complex Geometries and Profiles: The Y-axis CNC lathe machine excels in machining parts with complex shapes, profiles, and contours. It is commonly used for manufacturing components such as aerospace engine parts, medical implants, automotive transmission components, and hydraulic connectors.

5. Reduced Setups and Increased Productivity: With the capability to perform multiple operations in one setup, the Y-axis CNC lathe machine helps reduce the need for additional fixtures and repositioning of the workpiece. This reduces setup time, increases productivity, and minimizes human errors associated with multiple setups.

6. Thread Whirling and Milling Operations: The Y-axis CNC lathe machine can be equipped with additional live tooling, such as thread whirling attachments and milling capabilities. This enables the machine to perform complex thread profiles, helical milling, and other milling operations on cylindrical parts.

7. Automation and Integration: Y-axis CNC lathe machines can be integrated into automated production lines, allowing for seamless part transfers and improved overall efficiency. With the ability to communicate with other machines and robotics, it facilitates lights-out manufacturing and increases productivity.

The Y-axis CNC lathe machine provides advanced machining capabilities, enabling the production of complex parts with high precision and efficiency. Its versatility and ability to perform multi-axis operations make it a valuable asset in various industries, including aerospace, automotive, medical, and general manufacturing.

Technical parameter

NC | TAIWAN/GUANGZHOU | LNC/SYNTEC/GSK |

spindle | TaiWan Posa | A2-5/46 spindle |

X.Z axis servo motor | Japan YASKAWA | 1300 W |

Y axis servo motor | Japan YASKAWA | 750W |

spindle servo motor | Japan YASKAWA | 4.4 KW |

spindle servo pack | Japan YASKAWA | 5.5 KW |

lead screw/lead rail | TaiWan HIWIN/PMI | C3 , level two |

bearing | Japan NSK,Germany FAG | P4 level |

coupler for lead Screw | from Germany | high Precision |

Parameter | ||

Capacity | spindle bore | ¢56 mm |

Max. material diameter | ¢45 mm | |

Max. machining diameter | ¢350 mm | |

Max. length of machining | 200 mm | |

Max. travel of x-axis | 720 mm | |

Max. travel of z-axis | 280 mm | |

Max. travel of Y-axis | 155 mm | |

rapid speed (x-axis/z-axis/y -axis) | 36/36/20 m/min | |

reposition accuracy | 0.005 mm | |

Motor | spindle servo motor | 4.4 KW |

spindle speed | 3000 rpm | |

X/Z-axis servo motor | 1300 W | |

Y-axis servo motor | 750 W | |

servo motor for power unit | 750 W | |

Tools | gang type tools | 3--5 |

total living power tools unit | 4 | |

living tool holder size | ER20/25 | |

Other | total power | 7KW |

size( L x W x H ) | 2025*1385*1910 | |

N.W. | 2900 KGS |

Our Service

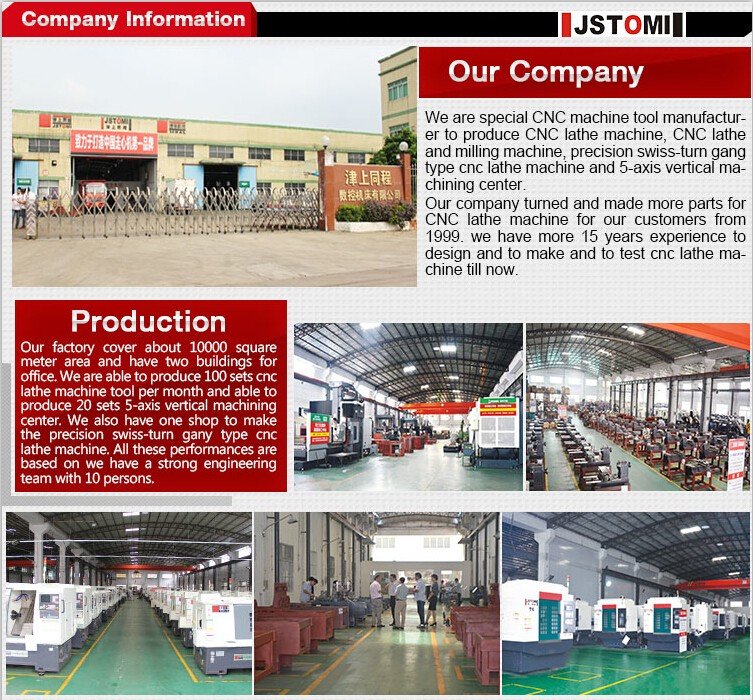

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front

in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools on

table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can also

according to your need to change the configuration. Thus pls provide us your machining drawing,

we are very glad to design a specific process solution for you and recommend you a proper cnc

machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong

machine tool research and development capability. We are very willing to offer you customized

highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly

and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the

Equipments for your market ,at the mean time the customers can enjoy the long-term technical

advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term

service to out customers.

Welcome to contact us if need any more information.

Copyright © 2018 Guangdong JSWAY CNC Machine Tool Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.